The Benefits and Advantages of Outsourcing PCB Design and Fabrication.

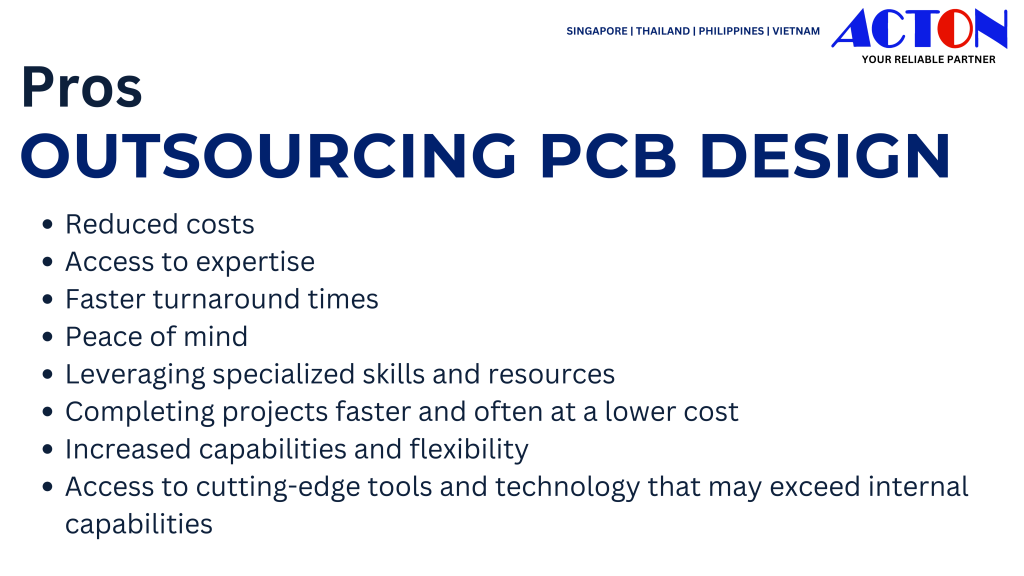

Outsourcing PCB design can offer benefits such as:

- Reduced costs

- Access to expertise

- Faster turnaround times

- Peace of mind

By outsourcing, companies can leverage specialized skills and resources, complete projects faster, and often at a lower cost. However, it’s essential to carefully evaluate potential partners, define requirements, and maintain open communication to ensure successful outcomes.

Outsourcing offers increased capabilities and flexibility. But for strategic or unique designs, it may be better to keep the process in-house.

Weighing the pros and cons and choosing the approach that best aligns with your specific project goals and requirements are crucial.

We’ll explore the potential advantages and address the common concerns around quality control, security, and communication.

What Is PCB Design and Fabrication?

PCB stands for Printed Circuit Board – board base for electronics that connect components like integrated circuits, resistors and capacitors. The PCB design process involves creating a layout for the components and circuitry, then fabricating the physical board.

Layout Design

The first step is designing the layout in PCB design software like Altium or Eagle based on your circuit schematics. You’ll place components, route copper traces to connect them, and add other features like mounting holes. Getting the layout right is key to a functional PCB, so many engineers focus their careers on PCB layout design.

Fabrication

After you create a layout, send it to a PCB fab to produce the actual boards. They use your design to photo-etch copper layers, drill holes and apply a mask for the circuit pattern. More complex boards may have 8 or more layers to allow for high component density

Assembly

The final step is assembling components onto the bare boards.

- Prototypes use manual assembly, while production uses automated lines.

- After soldering, the board is tested before shipment.

- In-house PCB production provides control but requires resources and knowledge.

- Many firms find outsourcing PCB design and fabrication to be a convenient, cost-effective option.

- PCB distributors transform circuit ideas into ready-to-use PCBs.

- Their expertise speeds up market entry, allowing teams to focus on core business tasks and product development.

Why Outsource Your PCB Design? The Benefits

Reduced Costs

Paying an experienced PCB design company likely costs less than hiring additional in-house engineers. Outsourcing also reduces infrastructure costs like software licenses and training.

Access to Expertise

Reputable PCB design firms have teams of engineers highly skilled in design, layout, and optimization. They stay up-to-date with the latest design standards and tools to ensure your PCB meets industry specifications.

Faster Turnaround

Because PCB design is their sole focus, outsourced firms can complete projects faster. They have streamlined processes to accelerate design, layout, prototyping, and testing.

Peace of Mind

Putting your PCB design in expert hands gives you confidence the job will be done right. Outsourced firms guarantee designs are optimized, components are properly placed, and the end product meets your requirements. They assume liability for any errors or omissions, allowing you to focus on your core business.

One-Stop Solution

The best PCB design distributors:

- Provides PCB fabrication and assembly, creating a seamless process from design to finished product.

- Source high-quality components that are compatible with your PCB design to ensure quality and reliability.

Using a single source for the entire PCB process reduces the risks of miscommunication and compatibility issues that can arise when working with multiple vendors. Outsourcing your PCB design makes good business sense.

While giving up control can be hard, finding an experienced design firm you trust allows you to leverage specialized skills and resources to complete projects faster and at lower cost.

A reputable distributor that also provides fabrication and assembly offers additional efficiency by handling the entire PCB process for you. For complex designs, outsourcing is often the smartest choice.

Top Tips for Choosing the Right PCB Manufacturer

Consider their capabilities

Make sure any PCB manufacturer/partner you consider has the capabilities to handle your specific design needs. Their capabilities and expertise level are important to evaluate.

- Do they offer below advanced PCB technologies if you require them?

Such as:

2. Do they have experience producing boards of similar complexity to your design?

Evaluate costs

While cost is a factor, don’t choose a PCB manufacturer based only on price. Cheaper does not always mean better, and you don’t want to sacrifice quality to save a few dollars. However, you also want to find a manufacturer that fits your budget.

Get quotes from different companies to compare, but also consider other factors like their capabilities, certifications, and reliability. Often a balance of high quality and fair price is the best option.

Check delivery and support

Look at the turnaround times the PCB manufacturer can offer to ensure they can deliver your boards when you need them. Also, consider the level of customer support they provide:

- Do they offer engineering support in case you have questions about your design?

- What is their process for resolving any issues that come up during PCB fabrication or assembly?

Their commitment to on-time delivery and customer service are important signs of a reputable PCB partner.

Consider a one-stop shop service provider

Using a PCB manufacturer that also handles assembly and component sourcing under one roof can simplify your life. A one-stop shop has oversight over the entire PCB process and ensures all parts are perfectly aligned, tested, and ready to use. This streamlined approach reduces opportunities for errors and miscommunications that can occur when working with multiple vendors.

Getting the most from your PCB Layout and Assembly

For high-quality PCBs that meet your specifications, choosing the right design and manufacturing partner is key. At Acton, our expert engineers utilize advanced software and techniques to create PCBs for your needs.

Acton: Your PCB Printing Singapore Partner

Our team of engineers has extensive experience with PCBs of all complexities, from simple prototypes to highly advanced designs. Whatever your PCB needs, we have the expertise to deliver.

Advanced PCB Capabilities

We utilize cutting-edge software and equipment to produce PCBs that meet the strictest requirements. Our facility can handle high-density interconnect PCBs, flexible PCBs, rigid-flex hybrids, and build-up layer PCBs.

We work with a variety of base materials to suit different applications. If you have a complex PCB that other suppliers struggle with, talk to us. We have the technical capabilities to bring your design to life.

Competitive Pricing and Responsive Support

By handling the entire PCB process in-house, we can provide:

- In-house management of the entire PCB process, ensuring competitive pricing while maintaining quality.

- Technical Support like an extended team to address queries and concerns, and expedite your product’s market entry.

- Acton technical teams are strategically located in Singapore, Thailand, and the Philippines for easy access and collaboration.

- Swift turnaround times, enhancing efficiency.

- Catering to all your needs, from prototypes to high-volume production. We are an ideal choice for diverse requirements.

With decades of experience and cutting-edge capabilities, Acton is the perfect PCB solutions partner. We offer responsive support, rigorous quality control, and competitive pricing to deliver PCBs that bring your vision to life.

Full-Service PCB Design and Fabrication Under One Roof

As a one-stop shop, Acton provides complete PCB design, prototyping, and PCB manufacturing services. Our in-house team of engineers handles everything from initial concepts to assembly and testing.

Expertise Across All PCB Types

Acton works with all PCB base materials and can produce simple single-sided boards or complex multi-layered PCBs. We also offer:

- Flexible printed circuits

- Rigid-flex PCBs

- High density interconnect (HDI) PCBs with microvias and build-up layers.

Our advanced capabilities allow us to handle challenging designs other suppliers can’t.

Design and Engineering Support

Acton’s engineers provide guidance throughout the design process to optimize your PCB layout. We review your schematics and board designs to identify any potential issues before manufacturing begins.

Our team is available to work with your engineers directly or make recommendations to improve the overall design and ensure it can be produced as efficiently as possible.

Advanced Fabrication and Assembly Equipment

Acton has invested in the latest fabrication and assembly technologies to produce high-quality PCBs.

Our facility is equipped with:

- Automated optical inspection (AOI) systems

- Flying probe and bed-of-nails testers

- Direct imaging systems,

- Pick-and-place machines.

These advanced equipment allows us to achieve high yields, tight tolerances, and consistent quality.

Advanced Capabilities for Complex PCB Layout and Assembly

Acton’s advanced PCB capabilities allow us to handle even the most complex designs with ease.

Diverse Base Materials

We work with a wide range of base materials, including FR-4, high-frequency materials like PTFE and ceramic-filled materials. We can choose the optimal material for your design based on factors like frequency, loss, and durability.

High Density Interconnect PCBs

Acton specializes in high-density interconnect (HDI) PCBs, which allow for more efficient use of board space. We can produce HDI PCBs with trace widths and spaces as small as 2 mils (0.002 inches). Our HDI capabilities include microvias, build-up layers, and via-in-pad technology.

Flexible and Rigid-Flex PCBs

In addition to rigid PCBs, Acton produces flexible and rigid-flex PCBs. Flexible PCBs utilize polyimide and polyester base materials that can bend and flex. Rigid-flex PCBs combine rigid and flexible PCBs, with flexible “bend areas” joining multiple rigid PCB sections. Rigid-flex PCBs are ideal for products where flexibility and durability are both important.

Advanced Assembly

We perform solder paste stencil printing, pick-and-place, reflow soldering, wave soldering, press-fit, and hand soldering and rework. Our technical team can also perform conformal coating and potting when environmental protection is required.

Acton has the experience and expertise to handle any PCB challenge.

Expertise in Gerber Files

Acton’s engineers are experts in Gerber file creation and handling. Gerber files contain all the data needed to fabricate your PCB, including drill files, solder mask and silkscreen layers, and copper layers. Our team utilizes the latest PCB design software to convert your electronic schematics into optimized Gerber files that can be used to produce high-quality printed circuit boards.

Acton is the perfect PCB partner. We become an extension of your team and provide responsive support to help you get to market faster.

Contact our technical team to get the best quotation via this link. You may also check our LinkedIn pages to get the latest updates. Message us on Facebook for a faster response rate.