What is a Thermal Interface Material?

Poor thermal contact is one of the most common causes of overheating and performance instability in electronics. A thermal interface material (TIM) improves heat transfer between components—such as chips, GPUs, and processors—and their heat sinks by eliminating air gaps that block efficient cooling.

Why Thermal Interface Material is Needed

Without an effective thermal interface material, a large portion of a component’s heat remains trapped at the interface. This thermal buildup accelerates degradation, reduces operating stability, and shortens component lifespan. A TIM enables efficient heat transfer, helping components operate within safe thermal limits over time.

What types of TIMs are there?

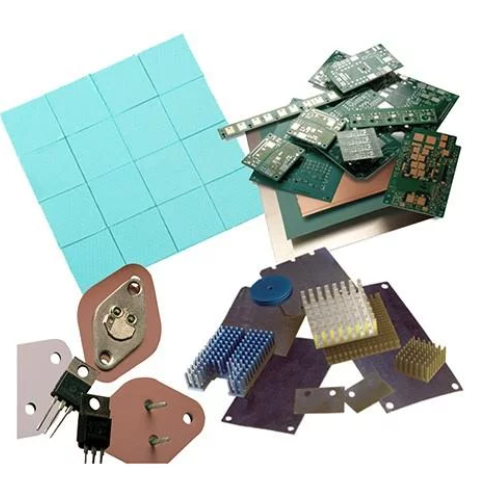

The three most common types are thermal pads, thermal grease, and thermal epoxy.

- Thermal pads are solid and pre-cut, easy to apply but less thermally conductive.

- Thermal grease is a paste that requires manual application but offers better performance.

- Thermal epoxy provides the best heat transfer but requires mixing and curing. Acton offers all three types so you can choose the best solution for your needs.

How do I apply a TIM?

Incorrect application of thermal interface materials is a common cause of thermal inefficiency, electrical risk, and rework. Each TIM type—pads, grease, or epoxy—requires a specific application method to achieve proper surface contact and safe operation.

Meanwhile, thermal grease requires spreading onto surfaces with a putty knife or spatula. Also, thermal epoxy requires thoroughly mixing the resin and hardener and applying before it begins to cure. In all cases, you want to apply firm and even pressure to ensure maximum surface contact.

Be very careful not to overapply, which can lead to excess TIM squeezing out and causing shorts.

Follow the directions for your specific TIM carefully. Contact our tech experts for further details

By engaging Acton early, teams avoid compatibility issues, repeated testing, and unnecessary material comparisons. This allows engineers to focus on core design and validation work while thermal requirements are addressed correctly from the start.

Need Tech Support?

Contact us for free expert advice