Your Reliable Partner

Power Electronics in Vehicle Electrification: Key Solutions

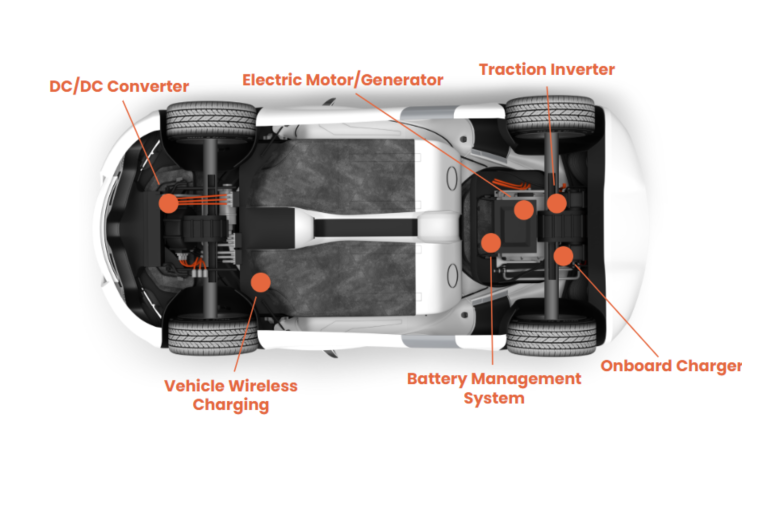

Power electronics are the foundation of modern electric vehicles (EVs), enabling efficient energy conversion, precise control, and safe power distribution. In vehicle electrification, components like DC/DC converters, traction inverters, and battery management systems (BMS) ensure seamless power transfer between the battery and the drive systems.

Explore how power electronics enable vehicle electrification, and how MLCCs, resistors, and circuit protection devices power key automotive systems.

Key Applications of Power Electronics in Vehicle Electrification

Acton Technology supplies Yageo components for power electronics in vehicle electrification. From MLCCs and resistors to circuit protection, we provide certified, reliable parts that ensure performance, efficiency, and seamless production for EV manufacturers and EMS teams.

Yageo Vehicle Electrification Components

Electric Motors and Generators

Features and Benefits

Electric motors and regenerative braking systems in power electronics rely on durable components to handle constant load and energy recovery.

- High-current resistors for motor control.

- Inductive components for noise suppression and power transfer.

- Automotive-grade capacitors to stabilize power pulses during acceleration.

DC / DC Converters

Features and Benefits

In vehicle electrification, DC/DC converters are used to step voltage up or down between high-voltage traction batteries and low-voltage vehicle electronics. Yageo’s components support:

- Voltage stability: AEC-Q200 MLCCs filter voltage fluctuations.

- Current sensing: Precision shunt resistors enable accurate monitoring.

- Efficiency: Low ESR capacitors minimize energy losses.

Traction Converters

Features and Benefits

Traction inverters convert DC power from the battery to AC for driving electric motors. As part of critical power electronics systems, Yageo ensures inverter reliability with high-performance passive components.

- High-temperature film capacitors for smooth AC output.

- High-power resistors for energy feedback and thermal stability.

- Low-inductance MLCCs for high-frequency switching performance.

Onboard Chargers

Features and Benefits

OBCs convert AC from the grid into DC to charge EV batteries. Yageo’s solutions include:

- Film capacitors for filtering and energy storage.

- High-voltage resistors to ensure safety and voltage regulation.

- Surge-protection components for durability during fluctuating grid conditions.

Battery Management Systems (BMS)

Features and Benefits

The BMS maintains battery health, prevents overcharging, and ensures long-term performance:

- Low-ohmic shunt resistors for accurate current sensing.

- MLCCs with stable dielectric materials for noise suppression.

- Temperature-resistant components to withstand battery heat cycles.

Wireless Charging Systems

Features and Benefits

Wireless EV charging demands precise resonance and power transfer:

- High-frequency MLCCs for minimal energy loss.

- Inductors and chokes to optimize resonance efficiency.

- Reliable circuit protection to prevent over-voltage events.

Vehicle Electrification Applications

In electric vehicles, power electronics components work as a connected network—from DC/DC converters to BMS—ensuring seamless energy flow and precise control. Each subsystem contributes to the efficiency, safety, and overall performance of the vehicle.

• Enhanced energy efficiency: High-quality components minimize power losses, improving battery utilization and extending vehicle range—critical for OEMs and manufacturers competing in the EV market.

• Improved safety and reliability: Automotive-grade components ensure compliance with strict standards (such as AEC-Q200), reducing failure risks and warranty claims.

• Optimized high-voltage performance: Reliable passive components withstand high currents and voltage stress, enabling stable operation even in demanding driving or charging conditions.

In vehicle electrification, every passive component such as capacitors, resistors, or protection devices impacts total system cost, reliability, and speed to market.

EMS providers and R&D engineers rely on trusted brands like Yageo for consistent performance and a stable supply chain, which are critical for scaling automotive production.

Challenges and Solutions in EV Power Electronics

Designing reliable EV power systems presents key challenges for EMS and R&D engineers:

- Thermal management: Components must operate reliably under extreme temperature cycles.

- Miniaturization: Growing demand for high power density within limited space.

- Cost vs. reliability: Balancing budgets with the need for certified, long-lasting components.

- Compliance: Ensuring components meet automotive standards like AEC-Q200.

Yageo's Vehicle Electrification Solution

Yageo delivers a comprehensive suite of automotive-grade passive components engineered to address these challenges:

• MLCCs (Multi-Layer Ceramic Capacitors): For stable filtering, EMI suppression, and energy storage.

• Resistors (Shunt & Thin-Film): For precise current sensing and voltage control.

• Circuit Protection Devices (TVS diodes, PPTCs): To safeguard sensitive electronics from voltage spikes.

services

Why Choose Acton as Your Yageo Distributor

Acton Technology is the authorized distributor of Yageo in the Philippines, Singapore, Thailand, and Vietnam. Moreover, Acton provides one stop solution and tech expert services for MLCCs, resistors, and circuit protection components that meet the demands of your power electronics and vehicle electrification projects.

With reliable sourcing support, technical assistance, fast delivery, and certified documentation, Acton helps EMS teams and R&D engineers keep projects moving and production running without delays.