In the world of power electronics, PCB power connectors play a pivotal role when it comes to bridging connections between electronic devices and peripherals. Not only do these connectors facilitate the transmission of electrical power, but they are also a major contributory factor in the seamless functionality of many devices. In addition, they offer numerous other benefits in order to maintain the reliability and efficiency of an electronic system. This blog post will cover all you need to know about these essential electrical component connectors, from what they are and how they work to their diverse applications and more.

Understanding PCB Power Connectors: What They Are and What They Entail

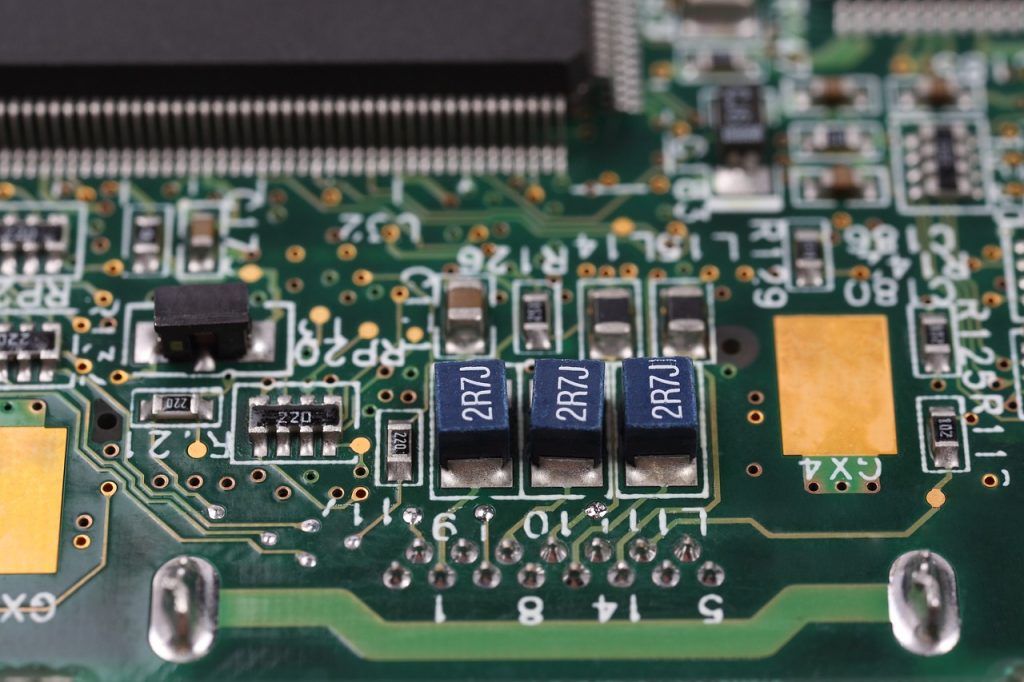

PCB (Printed Circuit Board) connectors are essential devices that connect various electronic components on a printed circuit board to external devices or other circuit boards. PCB connectors can be mounted on the circuit board in a number of ways, featuring different characteristics and specifications. Some devices may have more than one PCB and may also utilise various equipment to establish a connection within the unit. Available in an array of different shapes, and types, these components are beneficial in transmitting data, power, and signals reliably and efficiently.

The basic structure of a PCB connector encompasses many integral facets, including the housing and contacts. They are commonly made from non-substrate materials with copper circuitry layers but this may vary depending on the type of PCB. The ‘housing’ serves as the main pillar of mechanical support and is typically constructed from plastic. It plays a vital role in ensuring the alignment of the connector is correct. ‘Contacts’, on the other hand, are necessary for the actual connection and are usually made from a conductive metal.

Uncovering the Different Types of PCB Power Connectors: Exploring Diverse Orientations

Often referred to as building blocks of many electronic components and systems, PCB connectors comprise three main types of orientations: board-to-board, wire-to-board, and wire-to-wire. Board-to-board, as the name implies, connects two individual PCBs and is often used when various modules need to be linked within a system. These connectors can be connected parallel to each other or perpendicularly without the need for any cables or wires. These connectors, however, do have receptacles and pins to carry out their function.

The wire-to-board system utilises a wire or cable to facilitate a secure and reliable connection with the ability to be assembled or disassembled conveniently if required. The wire-to-board orientation is typically used when a connection has to be established between an external device or a peripheral and a PCB. There are different types of wire-to-board connectors, each with its own characteristics and benefits and the type needed will depend on the specification and design of the application.

Wire-to-wire connectors, also known as cable-to-cable connectors might be required during the prototype building phase. They may also be utilised if the cables need to be extended with one end of the cable being fixed to the wire permanently. These versatile connectors may also come with unique features, such as locking mechanisms and shielding, to ensure a stable connection with minimal interference. Furthermore, some wire-to-wire connectors may also be designed to be waterproof, making them ideal for outdoor use.

PCB Connector Types Based on the Application

Backplane connectors

Serving as a backbone of many electronic systems, these board-to-board connectors are used to transmit high-differential signals, single-end signals, and large currents. They are sought after by many for their modularity, versatility, and ease of use.

Automotive connectors

Designed specifically for use in the automotive industry, these connectors need to be highly reliable throughout their service life. This means the connectors must meet stringent requirements for durability and performance in harsh conditions.

USB connectors

There are four types of USB connectors: USB-A, USB-B, USB-C, and USB-Micro and are one of the most widely used PCB connectors in the electronic industry. USB connectors are commonly found in an array of devices, from cameras and smartphones to laptops and tablets and many other latest equipment.

Audio/Video connectors

These connectors as their name suggests are designed to transmit audio and video signals between devices. The type of signal, device compatibility, and the specific requirements of the audio/video equipment will all play a role in determining the choice of the connector needed.

Apart from the above-mentioned connectors, there are other types based on application and they include the following – D-sub connectors, fibre optic connectors, terminal block, memory connectors, circular connectors, modular/ethernet connectors and many others.

PCB Connector Types Based on the Design

High-speed connectors

These connectors are made specifically for high-speed applications and they need to be reliable and durable with optimal performance.

Solderless connectors

These connectors are used in the event when soldering isn’t practical and needs to be easily removed.

Low-profile connectors

Due to their small height and thickness, these connectors are ideal for use in compact spaces and in situations where a low profile is desired for functional or aesthetic purposes.

Waterproof connectors

As these connectors are designed to be resistant to water, they can be used in applications where they are exposed to water or other liquids.

Selecting the Right PCB Power Connector: Why You Can Rely on Smiths Interconnect’s Electronic Components

Since its establishment in 2007, Smiths Interconnect has become the leading provider of various engineered electronic components that can withstand the test of time. Known for pushing boundaries when it comes to performance, reliability and operating capability, Smiths Interconnect has become the top choice among many.

Let’s run through the key parameters that you need to consider when choosing the right PCB power connector for your requirements:

- Compatibility: A one-fits-all strategy isn’t the ideal plan when choosing PCB connectors. Make sure the power connector type you choose is compatible with your unique specifications and requirements.

- Safety: Ensure the connectors you purchase incorporate vital safety features such as locking mechanisms so that no failure or damage occurs.

- Performance: Good signal integrity is essential for precise signal transmission. Using an unsuitable PCB power connector can result in signal degradation. Therefore, make sure to verify this before you make your final decision.

- Reliability: Some connectors may perform differently under harsh conditions. While some may be designed to perform under a variety of conditions, some may not perform that well. Therefore, do factor in this as well.

Select the Best PCB Power Connector in the Globe with Acton Technology: Get Top-Notch Products Right to Your Doorstep

As one of Singapore’s trusted distributors of Smiths Interconnect products, we at Acton Technology understand the need to provide products and services that are on par with international standards. With this in mind, not only do we offer a comprehensive product range, but we also stay updated on the latest trends and work closely with our customers, ensuring their business runs at an optimal pace. Get in touch with our experts and find the best PCB power connector for your company.