Your Reliable Partner

Laird provides advanced product testing and measurement instrumentation services to help manufacturers worldwide design and build innovative technologies across sectors like automotive, telecommunications, data infrastructure, medical and consumer electronics.

Gap Fillers

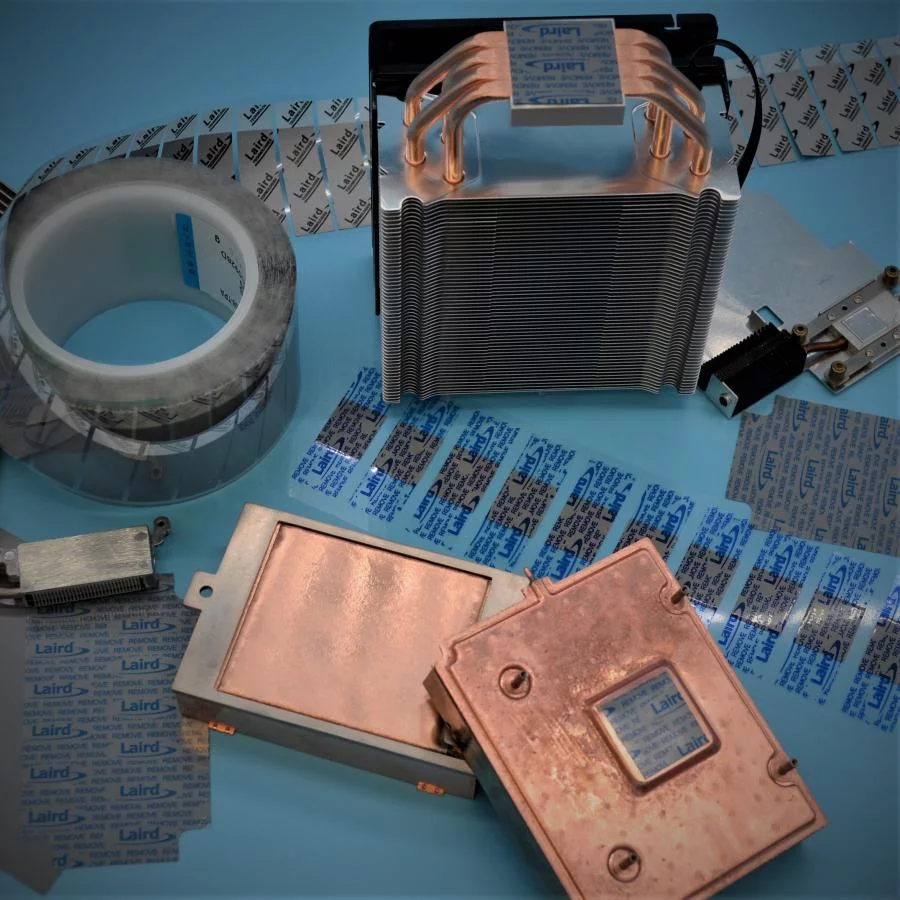

Thermal Interface Materials

What are Gap Fillers?

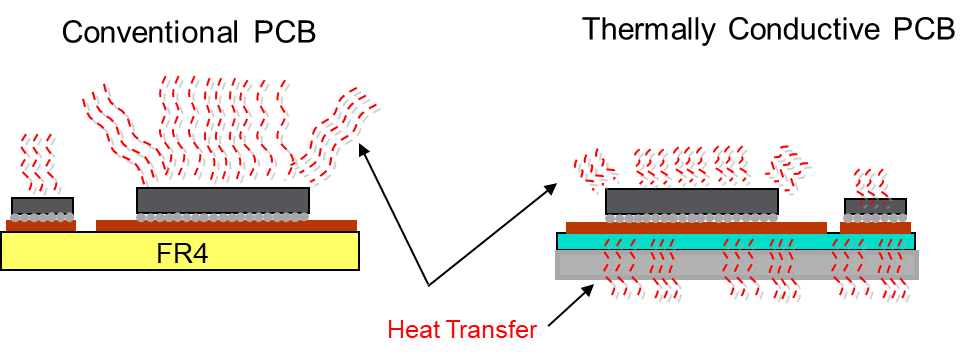

Thermal gap fillers are valuable aids as electronic component heat dissipation materials because of their thermal conductivity properties. They fill spaces and replace the air from them. Air is a poor conductor of heat. Aided by their thermal conductivity properties, gap fillers are scientifically engineered to increase overall heat transfer inside a device or system. They keep components cooler and within allowable thermal ranges.

A gap filler is a class of thermal interface materials that fills “a large gap” between heat generating and heat dissipating surfaces. Often, one gap filler can cover multiple heat sources within an application. The material can be placed across three different heat sources with varying heights. A gap filler material is expected to be compliant without generating too much pressure within the system. Gap fillers are usually silicone based because silicone has many attractive properties such as surface wetting, high thermal stability, and physical inertness. Newer offerings can contain no silicone. The silicone is normally used as the binder within a gap filler system. The silicone matrix is then filled with thermally conductive fillers – BN, ZnO, and alumina. These fillers make up the functional portion of the gap filler which gives it its thermal properties. Standard thicknesses of gap fillers tend to be 0.25-5mm (10-200 mils). They feature deflection without excessive pressure. Gap fillers need to be relatively compliant to achieve high deflections without generating excess pressure within an application.

The optimal properties of gap filler materials include low total thermal resistance, high thermal conductivity, and low contact resistance (good surface wetting). They should be easy to handle. There is a need for low outgassing/low bleeding. Excessive outgassing can cause silicone to condense and build up on optical applications.

How do They Work?

Thermal gap fillers are formulated in the lab and placed into electronic devices and systems to get into those small pockets of air, small gaps in space between hot components and a chassis or heat sink assembly. These gaps create thermal barriers to heat transfer due to the low thermal conductivity of air. Gap filler formulations provide the answer using their high thermal conductivity. They bridge what had been an air-filled interface. Gap fillers successfully transfer heat from sensitive components and help keep devices compliant and within prescribed heat limits.

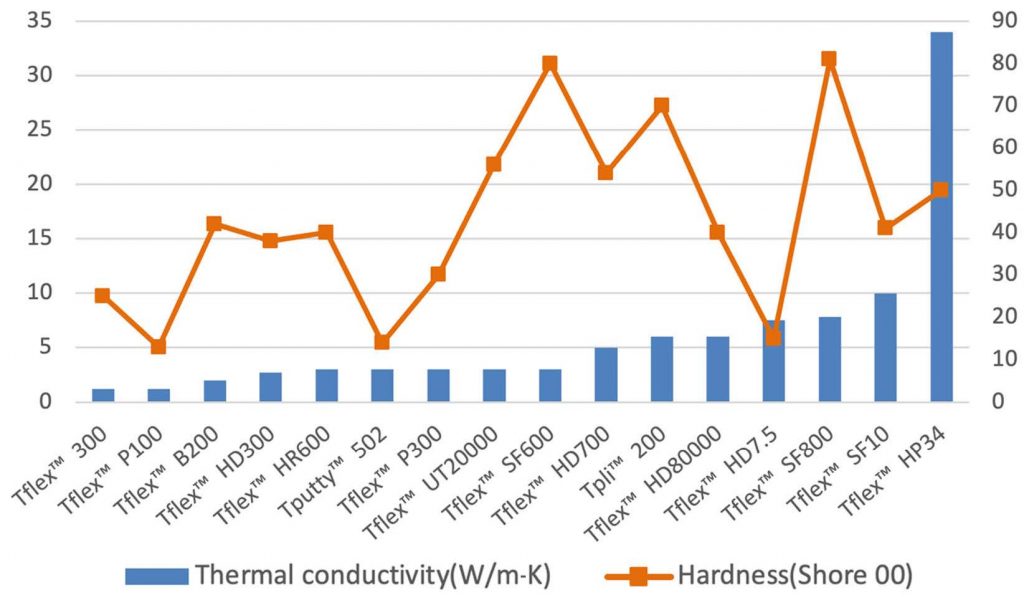

Gap Fillers Series

- Tflex 300TG

- Tflex 700

- Tflex HD90000

- Tflex SF600

- Tflex UT20000

- Tflex™ 300

- Tflex™ 50000

- Tflex™ 600

- Tflex™ B200

- Tflex™ HD300

- Tflex™ HD300TG

- Tflex™ HD7.5

- Tflex™ HD700

- Tflex™ HD80000

- Tflex™ HP34

- Tflex™ HR400

- Tflex™ HR600

- Tflex™ P100

- Tflex™ P300

- Tflex™ SF10

- Tflex™ SF800

- Tgon 800

- Tpli™ 200

- Tputty ™ 502

APPLICATIONS

- Telecom/Datacom – wireless infrastructure, routers, servers, memory modules, hard disk and solid-state drives

- Consumer – gaming systems, tablets, notebooks, smart home devices

- Industrial – LED lighting, automation, test instrumentation, motion control

- Aerospace and military – power supplies, controllers, drones, satellites

- Automotive – ADAS, infotainment, powertrain/ECU

Liquid Gap Fillers

What are Liquid Gap Fillers?

Liquid Gap fillers are thermally conductive gap filling materials used to enhance thermal transfer between an electronic component generating heat such as integrated circuits or transistors and a mechanical component carrying the heat to the exterior such as a heatsink.

How do Liquid Gap Fillers Work?

The liquid material is filling the gap between the hot component and the heatsink by flowing between the two components and making sure no air or void will remain between them.

Other Types of Thermal Fillers

Another common type of thermal filler are thermal gap pads. They are made of similar materials as liquid gap filler and provide similar benefits. They differ by two major points: gap pad are solid pads which are placed manually or with a robot onto the components; and liquid gap fillers are more like a putty which is being dispensed automatically thanks to a specific dispensing equipment onto the components.

Benefits of Laird’s Liquid Gap Fillers

These materials can be dispensed to fill large and uneven gaps in assemblies due to their super compliant nature; little to no pressure is transferred between interfaces. Laird’s dispensing product portfolio includes both one and two-part materials, as well as products specifically designed for vertical stability and consistent dispensing.

In 2019 we launched fully automated application capabilities for thermal pads and dispensables. You can end manual tasks through automation.

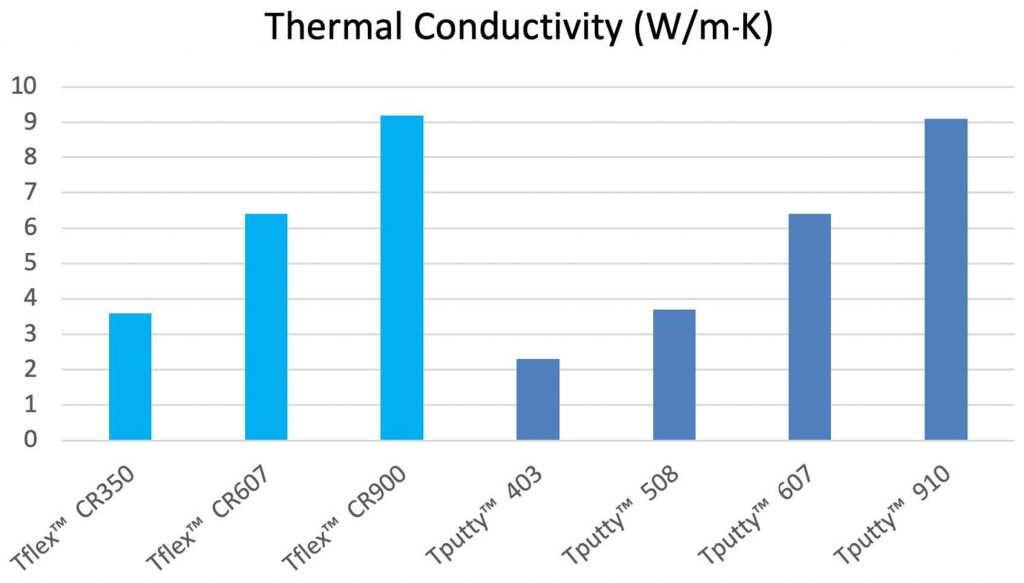

Liquid Gap Fillers Series

- Tflex™ CR350

- Tflex™ CR607

- Tflex™ CR900

- Tputty ™ 403

- Tputty ™ 508

- Tputty ™ 607

- Tputty™ 910

APPLICATIONS

• Telecom/Datacom – wireless infrastructure, routers, servers, memory modules, hard disk drives, solid state drives

• Consumer – gaming systems, portable devices, notebooks

• Industrial – power supplies, lighting ballasts, controllers, test and measurement

• Aerospace and defense – power supplies, drones, satellites

• Automotive – ADAS, infotainment, wireless charging units, lighting

Grease

Help end pump out and ensure reliability and optimal performance when minimum bond line, constant pressure and ease of screen printing are mandated.

Liquid Gap Fillers Series

- Tgrease™ 1500

- Tgrease™ 2500

- Tgrease™ 300X

APPLICATIONS

• Consumer – CPUs, graphics card, custom ASICs

• Telecom/Datacom –5G infrastructure, servers, routers

• Automotive – infotainment, autonomous driving and LED lighting

• Industrial – DC/DC Converters, IGBTs, discretes

• Aerospace and defense – avionics, power supplies, satellites

Tape and Adhesive

Ttape is a Thermally Conductive Tape which has a dual-purpose, providing excellent heat transfer along with reliable mechanical fastening. No additional fastening hardware is required in connecting your thermal dissipation device (heatsink) to your component. Double-sided Ttape is constructed from thermally conductive, pressure-sensitive acrylic. The resulting thermal interface material is cost-effective and reliable across various substrates with both high and low surface energy. The specialized chemistry of this tape renders them modestly soft and able to wet to many surfaces, allowing them to conform well to non-flat substrates, provide high adhesion, and act as a good thermal interface. Ttape is available in custom-cut parts with a release liner on both sides or kiss-cut parts on a roll.

Tape and Adhesive Series

- Ttape™ 1000A

APPLICATIONS

- Automotive ADAS

- Automotive Electronics

- Automotive Lighting

- Automotive Infotainment

- Automotive Powertrain/ECUs

- Avionics

- Base station/Power amplifier/Acitve antenna unit /small cell

- Computer servers

- DC-DC Converters

- Desktop computers

- Digital cameras

- Drones

- Graphic Cards

- Gaming Systems

- IGBTs

- Instrumentation

- Medical equipment

- Memory Modules

- Notebooks/Tablets/Portable Devices

- Optical module/transceiver

- Power Converters

- Power Supplies

- Printers

- Routers

- Satellites

- Servers

- Set top box

- Smart Home Devices

- Telecom cabinets

- Wireless infrastructure

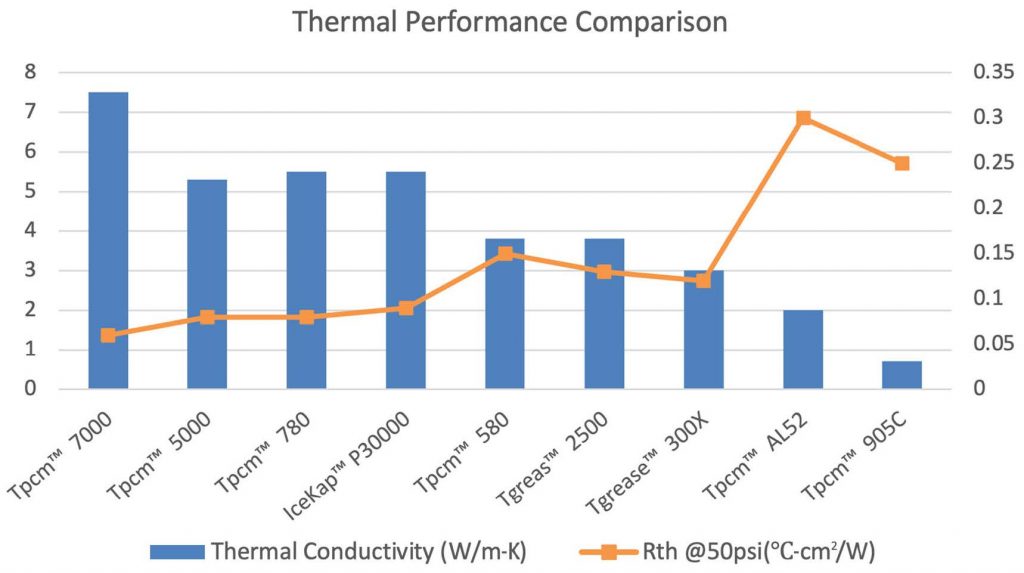

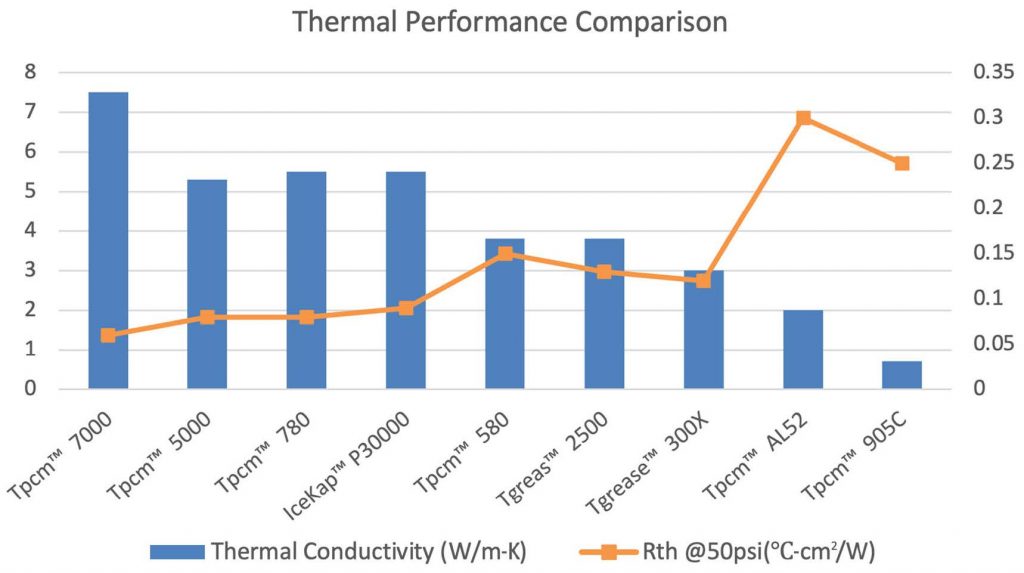

Phase Change

What are Phase Change Materials?

Thermal Interface Phase Change Materials are used to enhance thermal transfer between a hot component and a thermal solution like a heatsink. This enables the component to run at a lower temperature whereby increase speed and extending life. Phase Change Materials are used in the most demanding application across many industry segments. These include consumer electronics, telecom/datacom, automotive electronics, industrial electronics, medical and military/aerospace.

How do Phase Change Materials Work?

The first PCMs melted to a liquid state at temperatures between 50C-60C. This “phase change” allowed the material to wet the mating surfaces, and flow to a minimum bond line to provide the lowest possible thermal resistance, the best performance. Today most PCMs do not change state (melt) but soften at operating temperatures in the 50C to 70C range whereby providing the same advantages of wetting and minimum bond line but further provide much better long-term reliability (more resistant to pump out) than earlier materials that truly phase change to liquid. PCMs are generally used in constant pressure application (with some type of spring loaded heatsink).

Characteristics and Functions:

- Thermal conductivity range: 1 – 8 W/mK

- Thickness range: 0.125mm to 0.5mm

- Compliancy: UL 94V0, RoHs, REACH

- Easy to use; peel and stick format with top tabbed liners or automatable placement

Laird’s Phase Change Materials

Laird PCMs provide industry leading thermal performance, reliability and easy of use all at competitive prices

Phase Change Series

- Tpcm™ 200SP

- Tpcm™ 5000

- Tpcm™ 580

- Tpcm™ 7000

- Tpcm™ 780

- Tpcm™ 780SP

- Tpcm™ 900

- Tpcm™ AL52

APPLICATIONS

• Consumer – CPUs, graphics card, custom ASICs

• Telecom/Datacom –5G infrastructure, servers, routers

• Automotive – infotainment, autonomous driving and LED lighting

• Industrial – DC/DC Converters, IGBTs, discretes

• Aerospace and defense – avionics, power supplies, satellites

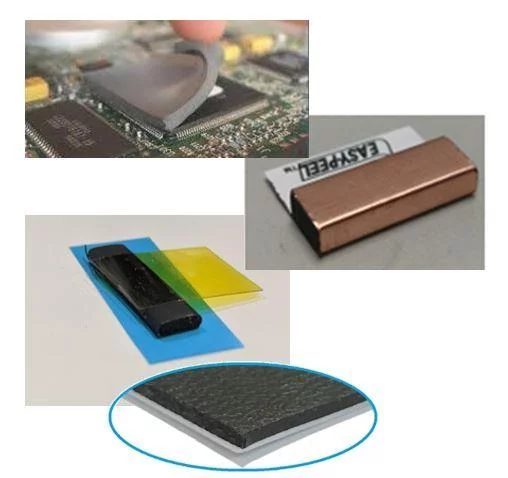

Specialty TIMS

As the challenges of thermal management materials morph into needed multi-functional capabilities Laird answers the call. Laird offers beyond the standard class of TIMs, Thermal Interface materials with unique dual functionality. Tgon™ 800, graphite sheets and pads offer good Z axis thermal conductivity and superb x-y heat spreading. OptiTIM™ has been ruggedized to endure sliding stresses of module insertions. Coolzorb™ pads offer EMI absorption while still providing soft, high thermal conductive gap filling. For large gap, high resilience interfaces, Laird offers GOF (graphite over foam) and COF (copper over foam) pads. See below more details

APPLICATIONS

- EMI Attenuation

- mmWave

- Optical Module

- Thermal Transfer

- Optical module/transceiver

- High Deflection

- Automotive Electronics

- Automotive Infotainment

- Automotive Powertrain/ECUs

- Automotive ADAS

- Radar

- Large Component Gap

- Sliding Connection

- EMI Shielding

- Servers

- Wireless infrastructure

- Telecommunications enclosure cabinets

- Automotive Lighting

- LED Lighting

- Notebooks/Tables/Portable Devices

- Power Converters

- Power Supplies

Specialty TIMS Series

- CoolZorb™ 200

- CoolZorb™ 400

- CoolZorb™ 500

- CoolZorb™ HD500

- CoolZorb™-Ultra

- GOF1000

- GOF2000

- GOF3000

- OptiTIM™

- Tgon 800

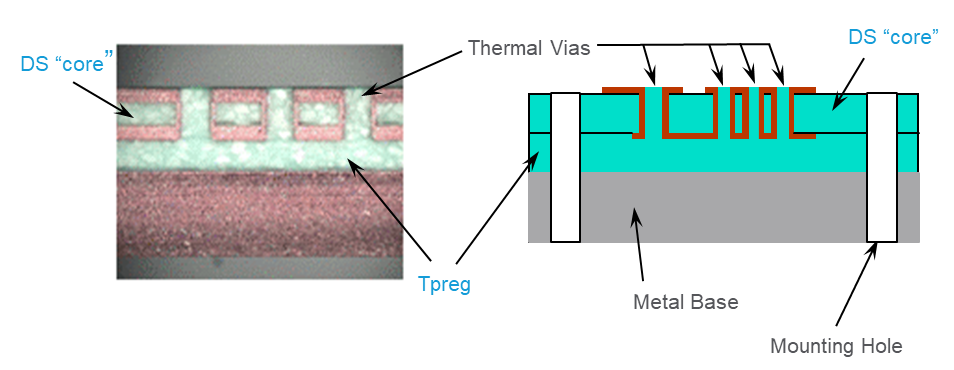

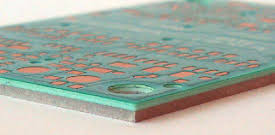

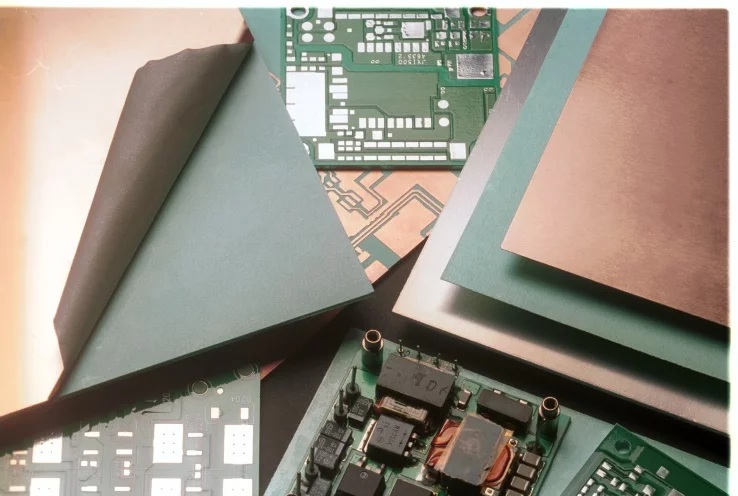

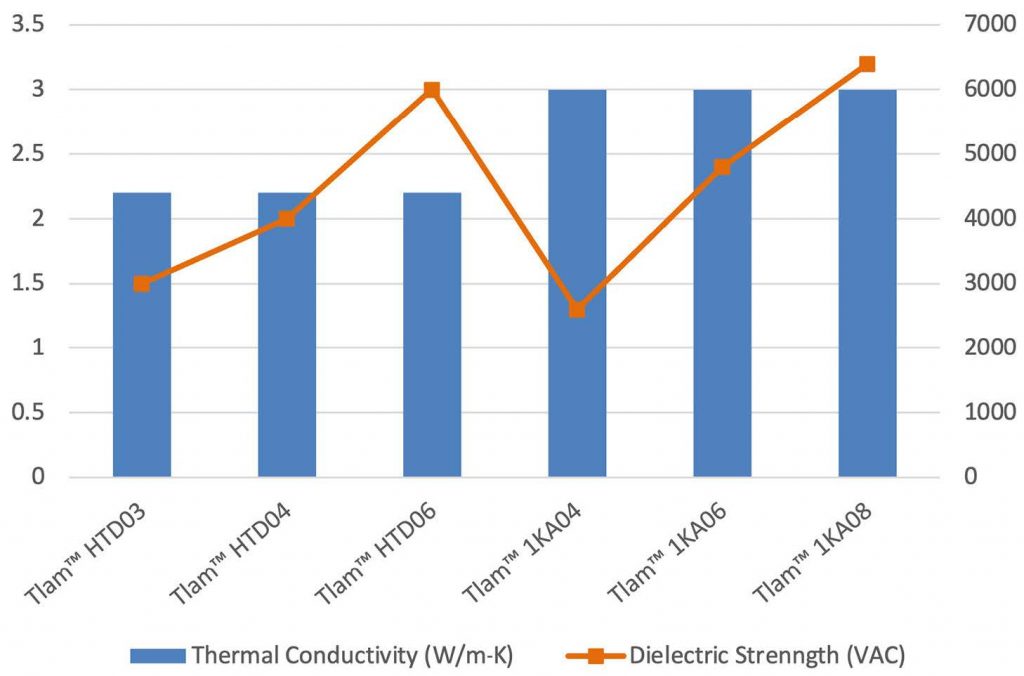

Tlam Thermally Conductive PCB System

Tlam™ is a thermally conductive insulted metal PCB substrate system used for heat dissipation in electronics circuit boards These boards are used in Power Supplies, DC-DC Converters, LEDs & Ballast Lighting, Automotive, Appliances, Commercial & Industrial Motor Drives, and Military & Aerospace Applications.

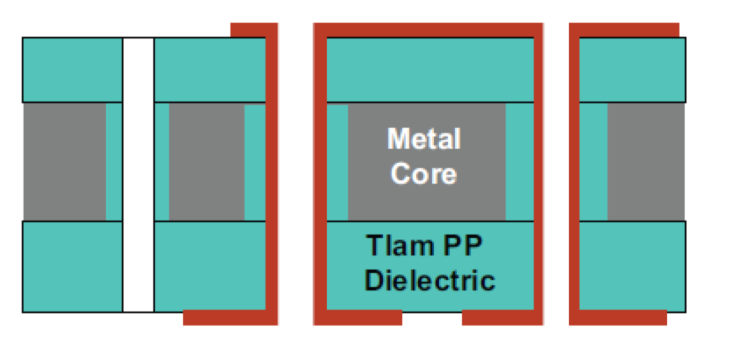

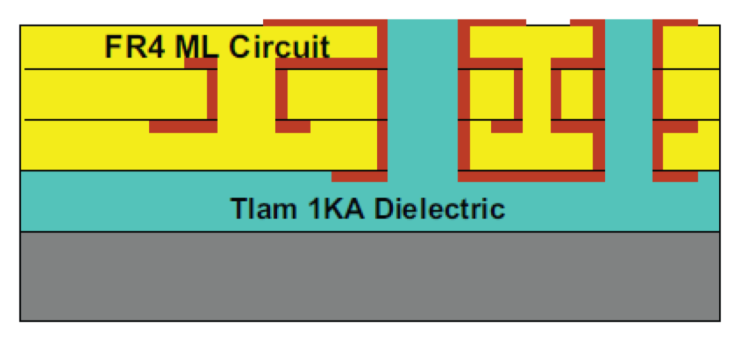

Tlam™ Building Blocks

Thermally Conductive Dielectric Tlam™ PP

Double Sided Laminate “Cores” Tlam™ DS

Insulated Metal PCB, Tlam™ SS

The heart of this system is the thermally conductive pre-preg, Tlam PP 1KA or Tlam PP HTD. These ceramically filled dielectric prepreg offers 8-10 times better thermal performance over FR4, while maintaining good adhesion and voltage breakdown properties. Tlam PP is a “B” State epoxy film providing room temperature stability for 6 months. Tlam PPs are provided in multiple thicknesses. Thinner films offer better thermal performance while thicker films offer better dielectric strength.

Tlam PPs can be used to build many different combinations of PCB laminates. The simplest Tlam is copper foil, Tlam PP dielectric and an aluminum base plate which acts as a heatsink and adds rigidity. Board complexity goes up from here offering multi-layer boards constructions and PCB structures can further include varying layers of Tlam PP and FR4 layers to give the thermal properties where need while maintaining cost effectiveness.

Tlam PP can be laminated with copper foils from 1/2 oz to 4 oz can be used aluminum or copper base plates ranging from 2.5mm to 6mm thick. This configuration is Tlam SS.

Further Tlam PP can be laminated on both sides with copper films to make traditional type PCB Cores. This configuration is Tlam DS.

For detailed information on Design and Fabrication:

- Tlam System Design Guide: Part 1: Performance and Reliability

- Tlam System Design Guide: Part 2: Manufacturability

- Tlam System Fabrication Guide

Other reference documents:

Tlam boards are used in Power Supplies, DC-DC Converters, LEDs & Ballast Lighting, Automotive, Appliances, Commercial & Industrial Motor Drives, and Military & Aerospace Applications.

Tlam Thermally Conductive PCB System Series

- Tlam PP 1KA

- Tlam™ PP HTD

APPLICATIONS

• Industrial – LED lighting, architectural lightingand street/highway/ parking/signal lighting

• Telecom – DC/DC convertors and base stations

• Automotive – motor control systems, power steering modules, ABS braking systems, headlights, brake lights, and daytime running lights

• Consumer – LCD LED backlighting units

• Industrial – solar voltaic, industrial voltage regulators, and power supplies

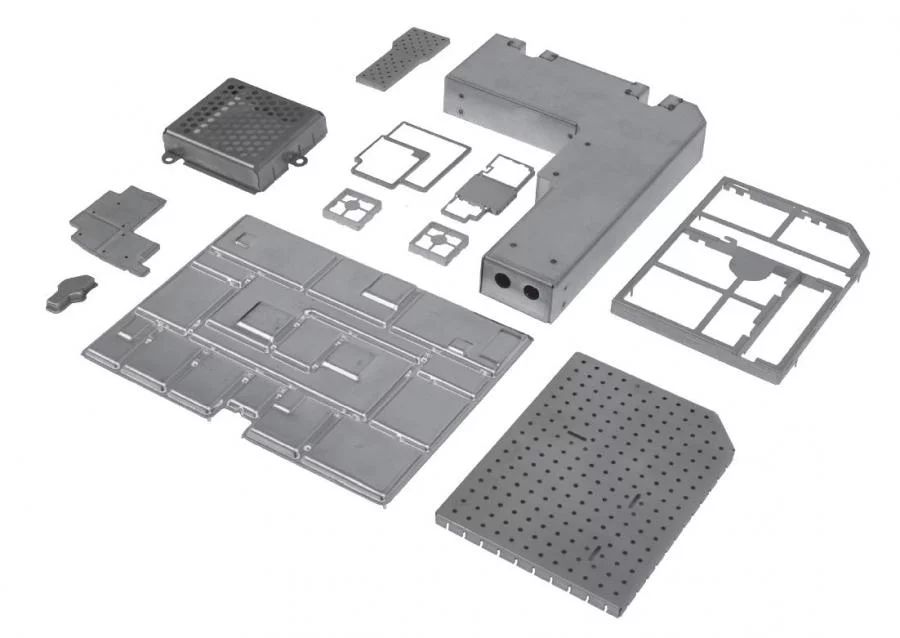

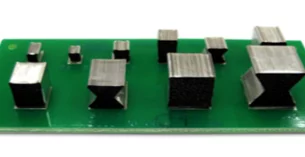

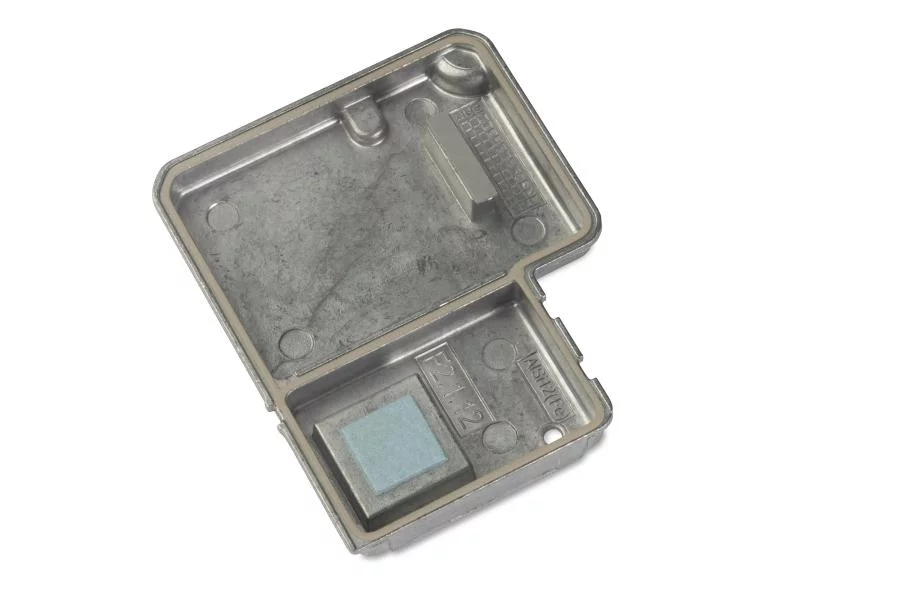

Board Level Shielding (BLS)

Surface Mount PCB Shields that Protect at the Component Level

Standard Surface Mount Shields

Standard surface mount shields are available in both one-piece and two-piece designs. One-piece shields offer six sides of EMI protection, with the sixth side being the board itself. One-piece designs offer economical shielding protection where access to covered components is not necessary.

Two-piece shields offer users the flexibility to inspect or repair shielded components without having to risk board damage by removing the entire shield or incur any tooling costs. The covers snap on and off with ease, which makes repair of the component under the shield quicker and easier and reduces board re-work.

There are no tooling costs associated with either the single-piece or two-piece standard designs. In addition, the standard designs are readily available for sampling and purchase.

Custom Surface Mount Shields

Design Engineering

Before contacting a Laird Performance Materials engineer, determine the right board level shield or contact design for the application. Based upon specifications, Laird experts will use the latest Pro-Engineering/AutoCAD systems to develop part designs in hours. Drawing upon extensive experience with application engineering, advanced design and materials engineering, Laird engineers will solve the most complex board level shield and contact problems. They and Laird technical specialists look beyond the initial component to the entire application. Each engineer will create the ideal finished product at the best value. Potential considerations include board layout, EMI shielding requirements and grounding terminations.

Accuracy and speed in the prototyping process are crucial in creating a successful product. Laird quickly responds within days with a prototyped part. By manufacturing with precision, the prototype meets the tolerances of a progressive die manufacturing production environment. If design modifications are necessary, Laird’s prototype department offers flexibility and addresses changes without affecting the delivery of the prototyped part. To ensure parts are delivered at optimum performance and meet specifications, all prototyped parts are 100 percent inspected on critical dimensions. Laird also provides pre-production support to help get your production line up and running more quickly. Parts designed in pre-production can be supplied while progressive die tools are being produced. With manufacturing plants throughout North America, China, Asia and Europe, Laird provides worldwide access to parts and offers the capacity to handle jobs of any size.

Conductive Foam Gaskets

Laird’s Ecofoam™ offers an innovative approach to traditional shielding and grounding by providing X, Y and Z-axis conductivity, enhancing the shielding effectiveness required to meet the increasing microprocessor speeds of today’s computer, telecommunications and other electronic equipment. The product is offered with a conductive PSA tape on one side. Ecofoam™ can be customized to your application by die-cutting, hole-punching, notching, and more. It is especially useful for odd-shaped applications which are difficult to shield with typical profile gaskets. Ecofoam™ is designed for low-cycling applications such as input/output (I/O) shielding and other non-shear standard connectors.

EMI Tapes

Benefit from thinner, conductive tapes of nickel/copper metalized fabric (with conductive pressure sensitive adhesive), ensuring superior EMI shielding, grounding, and flexibility.

– Conductive Fabric

Nickel/copper metallize fabric offers exceptional shielding, conformability and conductivity.

– Conductive Transfer Adhesives

Get EMI shielding, high electrical conductivity in Z directions, good adhesion, high shear properties.

-Double-sided Conductive Fabric Tapes

Double-sided adhesion, EMI-shielding, made of copper nickel-plated fabric, high conductivity in any direction.

– Single-sided Conductive Fabric Tapes

Get EMI-shielding, made of copper nickel-plated fabric, high conductivity in any direction.

Electrically Conductive Elastomers (ECE)

Block EMI. In any weather, anytime.

Sometimes, the standard silicone gasket just won’t do. Differing weather conditions, operating temperatures, levels of chemical exposure, corrosion, and environmental fluctuations call for gaskets that are designed to shield electromagnetic interference in environmental-specific settings. Our electrically conductive elastomers provide environmental sealing, excellent mechanical functionality, and electromagnetic shielding so your enclosures receive the best protection possible with optimal electrical performance.

How Laird Elastomers Secure Your EMI Shields

Your closure problem usually starts like this: you’ve constructed an effective shielding system using a metal housing and lid. But when you combine the flat surfaces of both units, you notice a slight opening. Suddenly, gas, liquid, or high frequency electromagnetic energy have an easy-access path to your shielding system, which can worsen under high pressure and corrosion. Thankfully, our resilient, conductive elastomers can seal this opening by conforming to surface irregularities in your shield’s enclosure. We offer versatile forms of elastomers such as:

Diverse filler particles within our line of ElectroSeal gaskets

Wire in solid and sponge elastomers, impregnated wire mesh, and expanded metals within our line of ElectroMet gaskets

These gaskets are available in:

Flat or die cuts

Molded shapes such as O-rings or intricate parts

Extruded / coextruded profiles or strips

Vulcanized-to-metal covers or flanges

Co-molded or reinforced seals

Form-in-place gaskets

Find or Design Your Conductive Elastomer

By combining the right form and type of elastomer, you can build an ideal sealing solution that blocks electromagnetic waves while providing sufficient conductivity across your shield’s enclosure, gasket, and lid junction. Browse our catalog of elastomers or contact an engineer through our customer service department to design a conductive gasket that’s right for you.

Explore Solutions

-ElectroSeal Conductive Elastomer Fabricated Components

Resolve differing weather conditions, chemicals and corrosion issues

-ElectroSeal Conductive Elastomer Extrusions

Gaskets for environmental sealing, EMI shielding or minimizing chemical exposure.

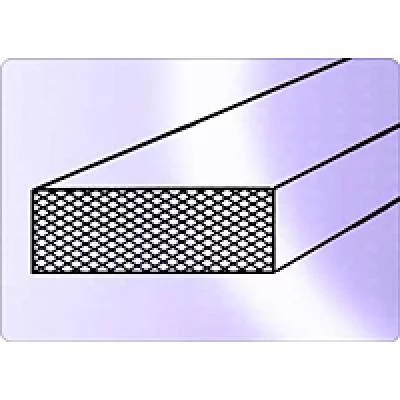

Fabric-over-Foam (FOF) Gaskets

Soft Shielding with Durable Design

EMI suppression isn’t easy to achieve if a gasket doesn’t fit your application’s requirements. Our fabric-over-foam gaskets are ideal for applications that require low compression force but still need high conductivity and shielding attenuation. If you’re looking to protect computer, telecommunications, or other equipment that requires soft shielding, we provide fabric-over-foam gaskets in a variety of shapes and thickness to meet your needs.

- Available in nickel/copper (Ni/Cu) and tin/copper (Sn/Cu), our fabric-over-foam gaskets deliver versatile galvanic compatibility and shielding. Other benefits include:

- Low compression forces throughout a compression range from 30 to 75 percent based on the shape of the fabric-over-foam gasket and its materials.

- Shielding effectiveness of >100 dB across a spectrum of frequencies.

- Gaskets that are UL 94 V-0 flame-retardant and halogen free (EcoGreen™) making Laird gaskets eco-friendly and exceed RoHS compliancy.

- High abrasion and shear resistance due to metallized fabrics that incorporate proprietary coatings that do not degrade shielding performance.

- Urethane, thermoplastic elastomer (TPE) and even silicone core material, which provide low compression and ensure long term reliability of gasket performance in a wide variety of applications.

- Find or Design Your Fabric-Over-Foam Gasket in the Virtual Design Center

We’ve expanded our line of fabric-over-foam gaskets to meet your most specific EMI needs and surpass regulatory requirements. Explore our catalog offered here or contact an engineer through our customer service department to create a fabric-over-foam gasket to meet your specific cross section shape, cut to length or unique die cut shape.

Explore Solutions

- T- Shaped Gaskets

Gaskets in T-shapes with a height of 3.8608mm are offered for effective EMI shielding

- Shapes

Available shapes for FOF Gaskets

- Square, Rectangle, D-Shape Profile FOF Gaskets

A variety of sizes of D-shaped profile gaskets has a conductive fabric over a foam core.

- Square Shaped Gaskets

Fabric-wrapped foam and additional square-shaped gaskets come in multiple sizes.

- Sculpted Foam Gaskets

UL94 V0 rated with superior compression and offering soft compression.

- Round Shaped Gaskets

Performance-proven round gaskets are available with 2.54mm height and 63.5mm width.

- RJ-11 Connector

Standard profiles are available along with custom designs and sizes.

- Rectangle Shaped Gaskets

Standard rectangular designs are complemented by quick-turnaround offerings.

- Rectangle Shaped Clip Gaskets

Rectangular, EMI-shielding gaskets come with a conductive fabric over a foam core.

- P- Shaped Gaskets

Custom-designed EMI shielding of varying shapes and sizes/quick turnaround.

- Oval Shaped Gaskets

Gaskets with unique oval shapes are for EMI shielding and come in multiple sizes.

- L- Shaped Gaskets

EMI-suppressing, L-shaped gaskets are offered in a variety of sizes.

- Knife Shaped Gaskets

Gaskets in L-shapes enable EMI shielding and are offered in a variety of sizes.

- J- Shaped Gaskets

Gaskets in a variety of heights protect against EMI disturbance in multiple environments.

- IEEE 1394 I/O Pin Connector

Standard or custom I/O gaskets for mouse, printer, plug-and-play serial port.

- Double Rectangle Shaped Gaskets

Quick design turnaround of unique double rectangle gaskets help you find solutions fast.

- Die Cut FOF Gaskets

Conductive foams add innovation by providing X, Y and Z-axis conductivity.

- D – Shaped Gaskets

Fabric-wrapped foam and additional D-shaped gaskets are offered in a variety of sizes.

- Complex Profile FOF Gaskets

EMI-shielding gaskets come with a conductive fabric over a resilient foam core.

- Clip Gaskets

Shielding effectiveness of >100 dB across a spectrum of frequencies.

- C-Shaped Clip Gaskets

Shielding effectiveness of >100 dB across a spectrum of frequencies.

- C-Fold Shaped Gaskets

Offering low compression forces throughout a compression range 30 to 75 percent.

- Bell Shaped Gaskets

Nickel/copper and tin/copper, fabric-over-foam offers galvanic compatibility/shielding.

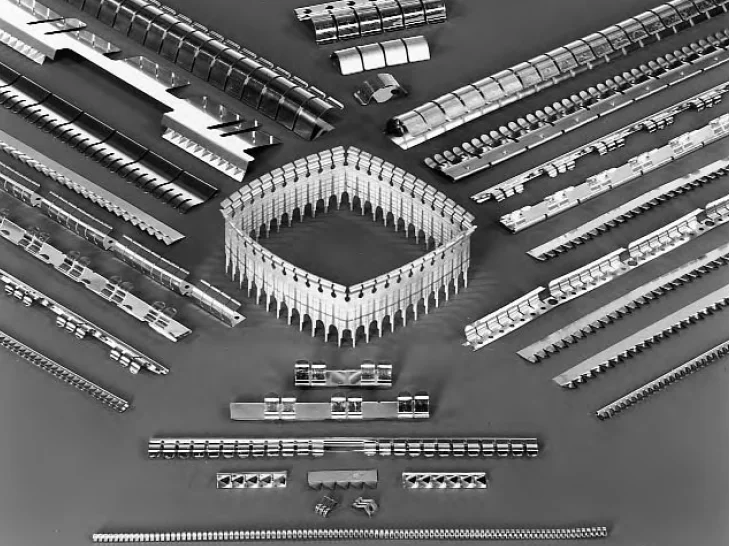

Fingerstock Metal Gaskets

Laird Performance Materials specializes in designing miniature parts of thin strip metal in quantities ranging from thousands to millions of pieces offers an extensive selection of enclosure shielding gaskets.

With over 500 standard parts, Laird has an off-the-shelf solution that meets your application’s requirements. Contact strips are used for grounding and shielding in high-frequency equipment and for forming large diameter contact rings. A wide variety of Beryllium Copper contact strips provides engineers and designers with flexibility in solving grounding and shielding problems. Various lengths, widths, thicknesses, contours and hole locations are possible for many of the standard catalog items.An “UltraSoft” low compression force version available for virtually every standard shielding product.

When custom designs are needed, Laird’s engineering staff helps construct efficiencies in performance, cost and manufacturability from the very beginning stages of the application.

Explore Solutions

- Tape-mounted Series

Versatile gaskets with non-conductive self-adhesive backing give tight, instant bond.

- Clip-On and Edge Mounted Series

An alternative to adhesive-mounted gasketing, clip-on gaskets are the choice.

- Slot and Track/Rail Mounted Series

Beryllium copper shielding gaskets are superior for slot or track/rivet mounted applications.

- Metal Connector Shields

Choose from a broad shielding line for protection within a wide range of pin connectors.

Form in Place (FIP) Elastomers

Molded for Performance

Laird manufactures form-in-place gaskets using an automated system for dispensing conductive elastomers. Our resilient, form-in-place gaskets provide reliable protection for compartmentalized cast or plastic enclosures and packaged electronic assembles.

Benefits of Our Form-in-Place Gaskets

If you’re looking for EMI components that are compatible with plastic, metal and plated substrates, our form-in-place gaskets can assist. Laird manufactures standard and custom form-in-place gaskets that optimize performance for a variety of electronics including telecom antenna(Radio/RRU/AAU/AAS), automotive(cluster/infotainment chassis shielding/radar/autonomous driving system), datacom(optical transceiver/ high speed connectors).

A total cost savings in the form of reduced raw materials, labor or assembly line.

Room temperature cure gasketing materials that eliminate the need for costly heat curing systems.

Easy-to-program operating system that permits quick tooling and prototype development within 24-48 hours.

High shielding effectiveness: 85-100 dB up to 10 GHz.

Excellent adhesion to a wide variety of metal and plastic substrates such as aluminum/casting alloys and stainless steel.

Contact Us for Form-in-Place Gasketing

Speak to one of our engineers about gasketing service or off-the-shelf solutions.

Explore Solutions

-RXP Moisture Cure Grades

No matter the adverse environment, we have the moisture-cured gasketing.

-HXP Heat Curing Grades

No matter the adverse environment, we have the heat-cured gasketing.

SMD Metal Contacts

Grounding contacts are SMD Beryllium Copper parts with reel packaging for general SMT processes, with excellent grounding performance.

Sample Kits and Accessories

See or order samples of Laird HXP heat-cured foam gaskets.

Soft SMD Contacts

Laird Performance Materials’ Soft SMD (Surface Mount Device) Grounding Contact is a foam cored contact with a metalized polyimide film outer covering. It is used for circuit grounding of SMT (Surface Mount Technology) devices. These contacts are designed to be solder reflow compatible and are suitable for automatic processing.

How do Soft SMD Contacts Work?

Laird’s soft SMD (Surface Mount Device) Grounding Contact is a foam cored contact with a metalized polyimide film outer covering. Usually, the contacts are packed with tape-and-reel which is the same as the package method of other components applied in surface mount technology. These contacts are solder reflow compatible and designed to be suitable for automatic processing.

How are Soft SMD Contacts Used?

Soft SMD Contacts are excellent solutions for electrically grounding. Usually, they can be soldered on PCB for grounding purpose or even shielding. The advantages are high compression range, automatic SMD processing, low weight and more.

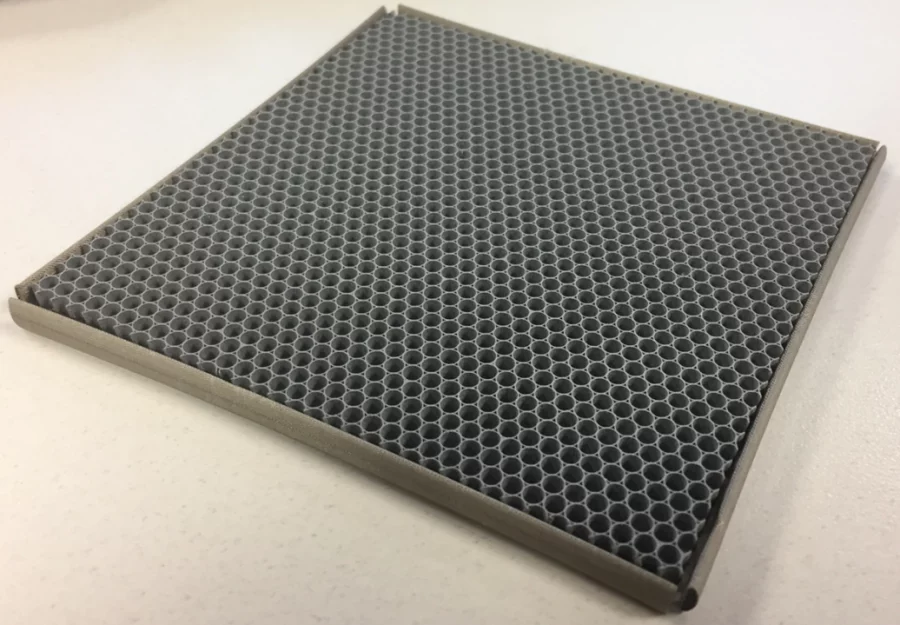

Vent Panels

Laird’s Ecofoam™ offers an innovative approach to traditional shielding and gavrounding by providing X, Y and Z-axis conductivity, enhancing the shielding effectiveness required to meet the increasing microprocessor speeds of today’s computer, telecommunications and other electronic equipment. The product is offered with a conductive PSA tape on one side. Ecofoam™ can be customized to your application by die-cutting, hole-punching, notching, and more. It is especially useful for odd-shaped applications which are difficult to shield with typical profile gaskets. Ecofoam™ is designed for low-cycling applications such as input/output (I/O) shielding and other non-shear standard connectors.

Wire Mesh Knitted Conductive Gaskets

Electronit All Mesh EMI Gasketing

ElectroNit™ All Mesh is a low-cost gasket for low cycling applications and is designed to offer the highest levels of attenuation.

Elastomer Core Mesh Gasketing

Elastomer Core Mesh is an optimum solution for combining excellent shielding performance with a high degree of elasticity.

Ultraflex Electronit BeCu Knitted Wire Shielding

UltraFlex™ CuBe Mesh offers resiliency for consistent, point-to-point contact requiring the lowest compression forces among all other shielding materials.

Electromesh Tape

ElectroMesh tape has a double layered strip of knitted wire shielding providing effective EMI shielding and grounding for electrical cable assemblies.

Clips and Washers

Clips, Washers, Tape, etc., are useful in applications requiring EMI protection.

Structural Absorbers

Flexible solutions

Whenever pre-cut materials will not fit your unique design, our full line of epoxy, silicone-based and thermoplastic molded, casted and machined absorbers can give you the attenuation you need. Absorber materials can be precision-machined or custom molded/injected in a variety of complex shapes. Magnetically loaded but not electrically conductive, they also can be placed directly in contact with circuitry. Certain compounds loaded with specific fillers may be used in high volume applications that require reduction of interference and enhanced performances through absorbers material. Because of their low out-gassing properties, these materials may be suitable for space applications.

Benefits of our Injection Molded, Machined and Casted Absorbers

- Withstands temperature cycling

- Reflow compliant grades

- Easy to bond and release

- Fully customizable solutions possible

- Weatherproof

- Excellent abrasion resistance

- Low to high volume compliant process

- Suppresses surface currents

Find or Design Your Absorber

Using Laird-manufactured parts, our team of global experts and engineers create a custom design experience that is unrivaled by our competitors. Explore our robust line of absorber products or contact an engineer through customer service to discuss your next solution.

Explore Solutions

- Injection Molded Thermoplastic Absorbers

See ECCOSORB MF PA, our high temperature, magnetically loaded thermoplastic Polyamide absorber.

- Machinable Stock

ECCOSORB® MF500F is popular as a waveguide absorber and with attenuators and coaxial lines.

- Eccosorb CR Compounds

Learn the benefits of ECCOSORB castable absorbers available in several resins.

Low Loss Dielectrics

Configured to Defend

With the recent progress of wireless telecommunication, intelligent satellite systems, and the Internet of Things (IoT), there’s a constant demand for low-loss dielectric materials. The exact properties of these materials – the composition, purity, and processing conditions – are critical to their performance and endurance over time. Laird has a full line of state-of-the-art, reliable dielectrics products that range from 1.05 to 30 dielectric constant in rod, sheet form or even 3D shape, rigid or molded. We can custom fabricate anything to your needs. What’s more, we have the modelling and testing capabilities to ensure your project is completed with ease and perfection.

Benefits of our Low Loss Dielectrics

- Various form factors: compressible or rigid closed cell foam, elastomer, thermoplastic

- Adjusted to multiple dielectric constants

- Low loss tangent

- Rigid or flexible materials

- High / low t° stability

- Adhesive options available

Find or Design Your Absorber

Using Laird-manufactured parts, our team of global experts and engineers create a custom design experience that is unrivaled by our competitors. Explore our robust line of absorber products or contact an engineer through customer service to discuss your next solution.

Explore Solutions

- Low Dielectric Thermoset Materials

ECCOSTOCK 0005 is a translucent polystyrene based thermosetting exhibiting low loss dielectric properties

- Powders, Resins and Adhesives

ECCOSTOCK FFP is a powder curing into a rigid foam, perfect to fill cavities.

- Low Dielectric Foam Products

Eccostock LoK is a low dielectric constant, low loss and low weight thermosetting plastic for RF and microwave insulation.

- Controlled Dielectric Thermoset Materials

ECCOSTOCK HIK500F is a low loss stock with adjusted dielectric constants up to 30 and over 200°c temperature resistance.

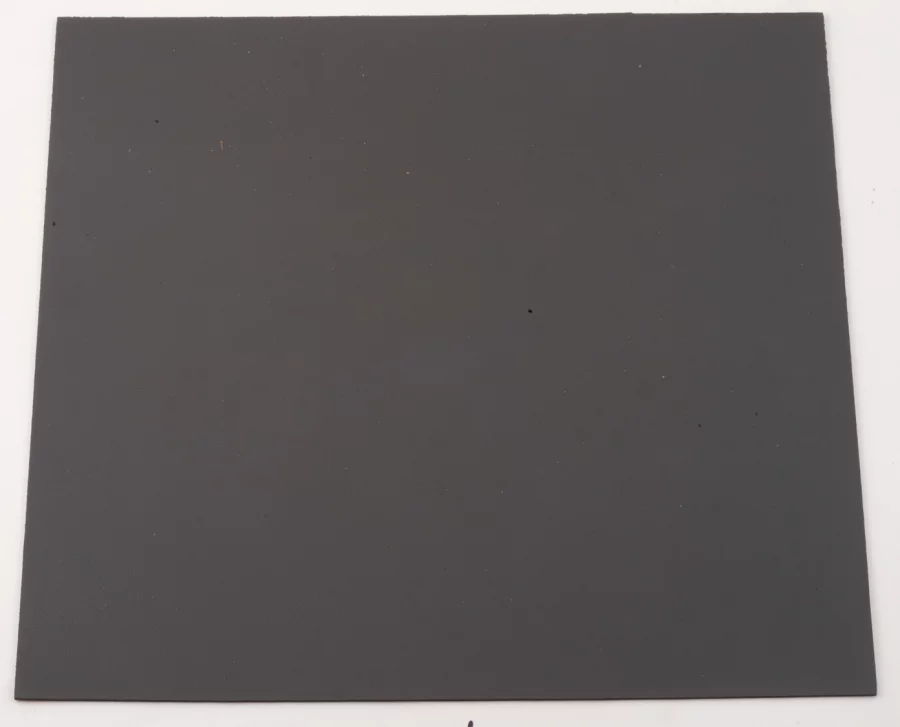

Thin Elastomer Absorbers

High Performance

Dampening resonance in enclosed space applications is a typical engineering challenge. Our multiples grades of silicone-based absorbers can lessen a wide variety of problems including cavity resonance challenges. Designed for all environmental situations, our elastomers provide superior weather resistance.

The full range is designed to operate at various frequencies with single band and broadband grades from a few hundreds of Mgz to above 100 Ghz. Whatever the issue, our absorbers can help your solve it.

Benefits of Our Elastomer Absorbers:

- High temperature operation up to 170°C

- High mechanical strength

- Custom shapes and components available

- PSA available

- UL rated grades

Find or Design Your Absorber

Using Laird-manufactured parts, our team of global experts and engineers create a custom design experience that is unrivaled by our competitors. Explore our robust line of absorber products or contact an engineer through customer service to discuss your next solution.

Microwave Absorbing Foams

Microwave absorbing foam is a lightweight, cost effective solution addressing today’s challenges in communication infrastructure. Single and multilayer structures consist of tuned absorbing layers with specific dielectric gradients to obtain its best possible matching with the impedance of air. These broadband absorbers are available in different thicknesses to target various frequency ranges.

Explore Solutions

- Broadband Free Space Isolation Absorbers

Provides an energy isolation barrier for components with a minimum of reflection.

- Broadband Free Space Reflectivity Absorbers

The ideal solution to reduce unwanted reflection from surfaces. Available in various grades to target the best performance versus frequency range

- Convoluted Broadband Free Space Reflectivity Absorbers

Convoluted broadband microwave foam absorbers are light in weight and address multiple incidence angle scenarios.

Microwave Absorbing Gap Fillers

Soft Absorber

Microwave absorber gap fillers are very soft absorber pads with low deflection force upon compression. This soft, conformable absorber eliminates unwanted signal noise while also acting as a gap filler that reduces further coupling.

The Softzorb product family can be used to fill the air gap between electronic components and structures to reduce coupling without stressing components or structures. This product offers design engineers valuable flexibility and enables them to maximize the performance of their products.

Ruggedized Specialty Microwave and Custom Magnetic Absorbers

Military strong

For free space reflectivity reduction, cavity resonance as well as tuned functionality, Laird can offer military- and aerospace-compliant products and technologies.

Complex, highly sensitive military/aerospace electronics must perform flawlessly, every time and often in extreme environments across land, air and sea.

Find a selection of qualified and running grades in military aerospace applications.

Sample Kits and Accessories

Durable bonding solutions

Absorber tapes and adhesives to use with our absorbers.

Absorber patching kit to solve your short notice EMC issue across the frequency range with a selection of multiple materials. These solution kits are customized by region, select the correct one.

Hybrid - ISE

Merged Functionality

Laird Hybrid-ISE solutions merge thermal, EMI shielding, and microwave absorbers into a single-engineered package to meet your demands for cutting-edge products. Today’s electronics are creating more heat, are operating at higher frequencies, are needing to fit into smaller packages, and are relying on precise signals from their antennas to compete in an ever-evolving market landscape. Laird solutions are targeted directly to meet these challenges and needs.

Metal - ISE

Enhanced Functionality

Metal-ISE solutions utilize Laird’s extensive automation capabilities to enhance precision metal components with our vast catalog of thermal and EMI materials. Laird is in a unique position to offer complete thermal and EMI solutions from one manufacturer, giving you efficient manufacturing and a lower total cost of ownership. Laird is your total solutions provider.

Structur - ISE

Material Science Meets Structural Components

Laird Structur-ISE improves the performance of smart structural components, enabling them to provide more than just physical strength to your device. Device enclosures are tasked with more than just physical and environmental protection. Sensors and antennas need to interact with the outside world. Today’s sensors and antennas need smart structural materials to keep out unwanted interference and noise as well as ensure the desired signals pass through with no signal loss or degradation. Traditional plastics no longer meet these demands and need to evolve. Laird Structur-ISE is the solution.

Textil - ISE

Application of Smart Fabrics

Laird Textil-ISE utilizes selectively-plated flexible fabrics (stretchable and non-stretchable) to create assemblies providing more than just a conductive path. The Textil-ISE product family provides a solution for heating elements, capacitive sensors, and pressure switches, incorporating flexible fabrics as the basis for these solutions. The flexible nature of Textil-ISE allows its application in environments which are unsuitable for traditional circuit design.