Your Reliable Partner

Motor Drive Solutions: Integrated Drivers vs. Gate Drivers

Choosing the right motor drive solution for industrial performance.

Motor drives are at the core of industrial application using motors — but selecting the wrong control solution can compromise efficiency, thermal management, and system reliability.

Selecting the right motor drive solution is critical to delivering the high current required by modern industrial motor drives. Engineers must choose between monolithic integrated drivers or gate drivers paired with discrete MOSFETs. This article outlines the advantages and trade-offs of each approach to support optimal design decisions.

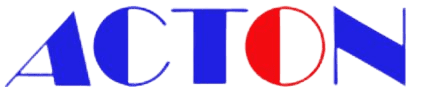

Monolithic Motor Driver Solutions

Monolithic motor drivers integrate control logic, protection features, and power MOSFETs onto a single silicon die. This implementation offers more precise current measurement, robust protection (OCP, OTP), and a compact footprint as well as better power density.

Monolithic solutions are typically limited to 80–100V and about 15A. They are ideal for high-volume, low-to-medium voltage industrial motor drives where size and integration are priorities. For example, the MPQ6541 from Monolithic Power Systems supports up to 8A continuous current in a compact 6mm x 5mm package, eliminating the need for external current sensing.

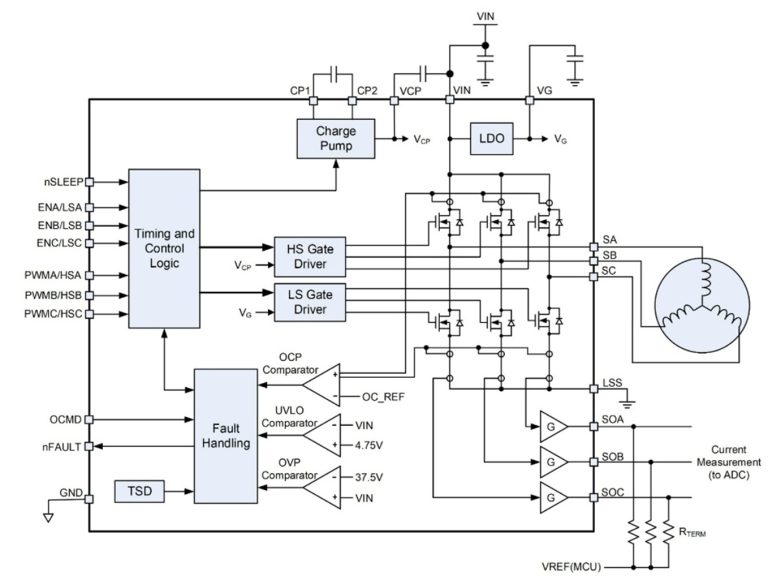

Gate Drivers with Discrete MOSFETs

For higher voltage (>100V) and high-current motor drive applications, using a gate driver IC with external MOSFETs is necessary. While the solution size increases, it offers better scalability, thermal performance, and higher power handling — important for demanding industrial motor drives.

The MPQ6533, a 3-channel gate driver with integrated diagnostics, exemplifies this approach. However, it requires six external MOSFETs, resulting in a larger PCB footprint.

Cost Consideration

For higher voltage (>100V) and high-current motor drive applications, using a gate driver IC with external MOSFETs is necessary. While the solution size increases, it offers better scalability, thermal performance, and higher power handling — important for demanding industrial motor drives.

The MPQ6533, a 3-channel gate driver with integrated diagnostics, exemplifies this approach. However, it requires six external MOSFETs, resulting in a larger PCB footprint.

Lower-power industrial motor drives

Monolithic drivers are more cost-effective due to integration, reducing the need for external components.

High-power industrial applications

Gate driver solutions are more economical, leveraging lower-cost, high-performance discrete MOSFETs.

Space constraints

In designs where PCB space is limited, the compact size of monolithic drivers can justify higher costs.

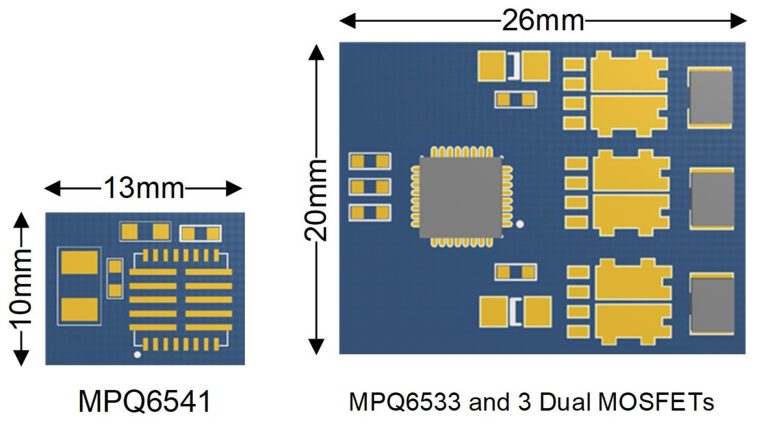

Solution Size and Thermal Management

Monolithic drivers occupy less PCB space, as seen with the MPQ6541 at 130mm². Gate driver solutions like the MPQ6533 setup require about four times more area.

However, larger discrete MOSFETs offer superior thermal dissipation, a key factor for high-power or harsh environment industrial motor drive applications.

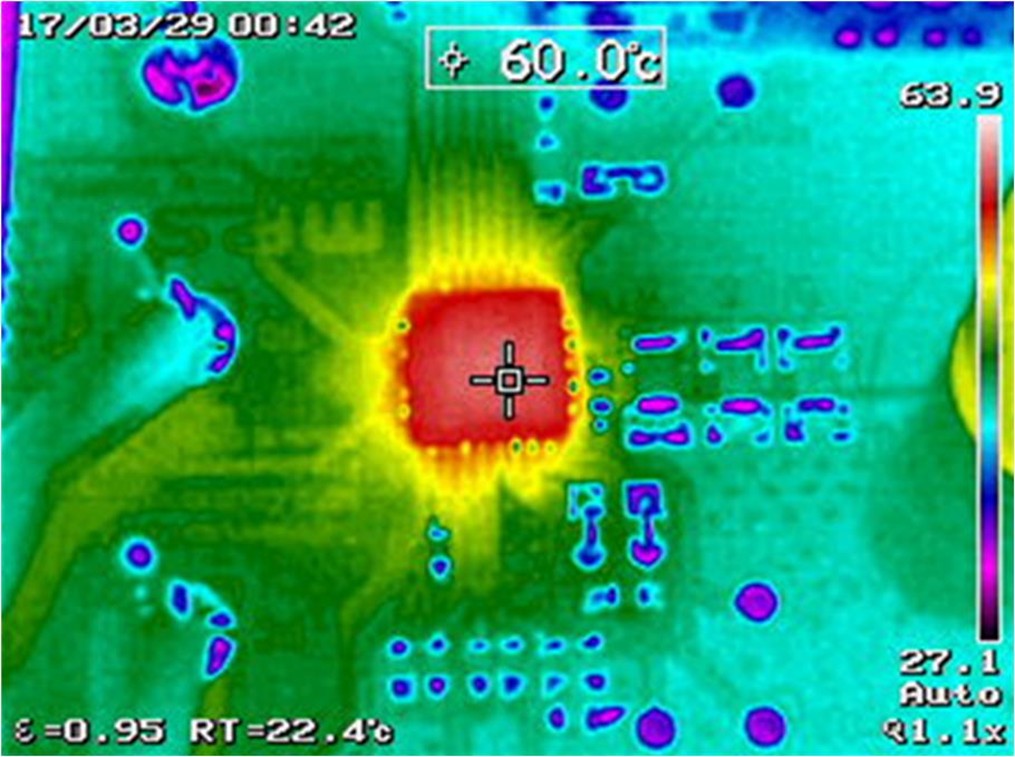

Thermal Considerations

Thermal management is critical when choosing between integrated and gate driver solutions. Package size, PCB design, and heat dissipation capabilities directly impact system reliability and performance.

Monolithic drivers

Smaller packages result in higher thermal resistance; careful PCB design is necessary to manage heat effectively.

Gate driver + discrete MOSFET solutions

Larger external MOSFETs provide better heat dissipation, making them suitable for high-power and harsh environment motor drive systems.

Design strategies

Multi-layer PCBs with internal planes can significantly improve heat management for monolithic motor drive designs.

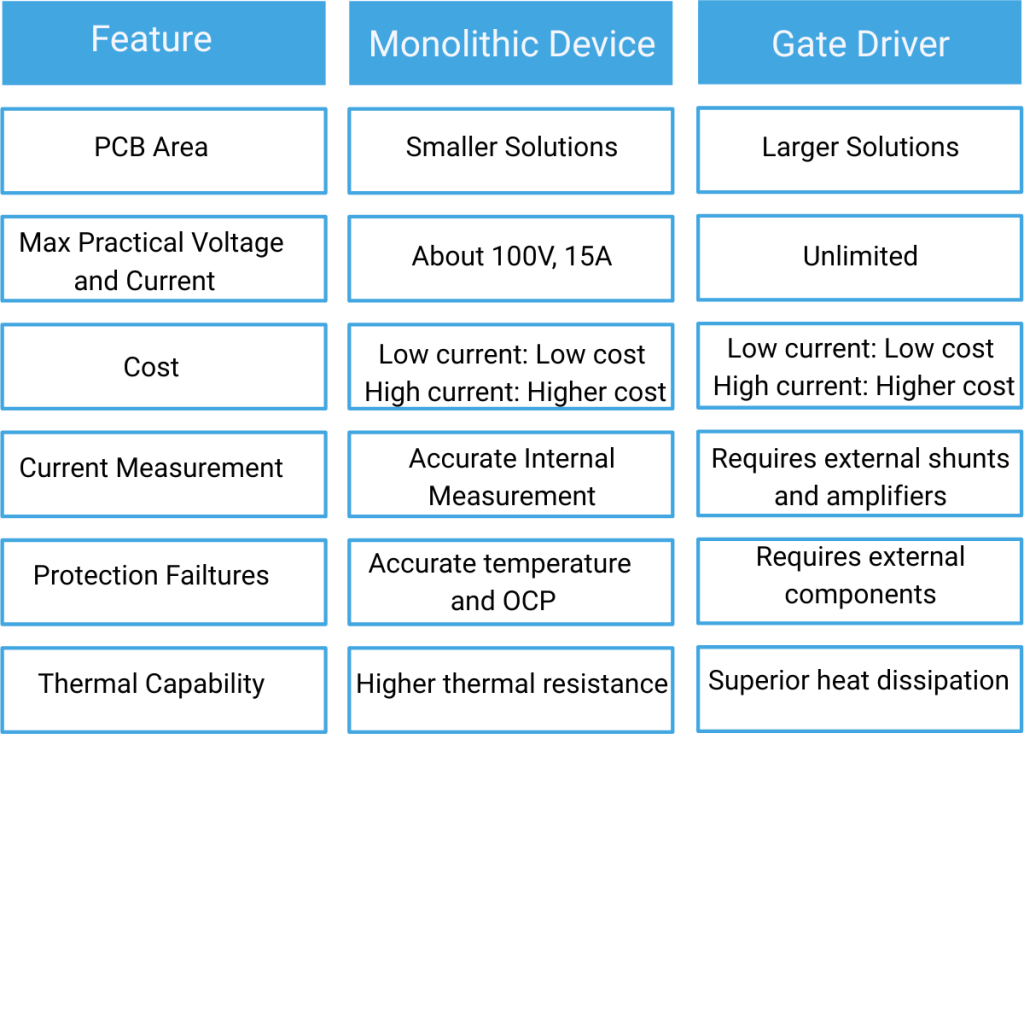

Summary of Main Differences Between Monolithic and Gate Driver Solutions

Monolithic drivers offer compact integration for low-to-medium power needs, while gate driver solutions deliver higher voltage, current, and better thermal performance for demanding applications.

(Refer to the table for detailed comparison.)

services

Motor Drive Solutions from Acton Technology

The choice between monolithic drivers and gate driver solutions depends on system requirements such as voltage, current, thermal performance, and available space.

For compact industrial solutions, monolithic drivers are ideal. For high-power, high-voltage systems, gate drivers combined with discrete MOSFETs are a better fit.

Need help choosing reliable motor drive solutions?

Acton Technology offers a full range of motor drive solutions from Monolithic Power Systems (MPS) to meet your industrial application needs.

Contact us today at contact@acton-tech.com to find the right motor driver solution for your project.

Choose the Right Components for Industrial Success

Acton Technology offers a comprehensive selection of MPS driver solutions to meet your industrial application needs.

Click HerePower Module Issues

Know more about common power module issues to ensure optimal performance and system longevity.