Your Reliable Partner

Burn-In Socket Solutions for High-Reliability Testing

Engineered for extreme temperatures and precision, the QN Series Burn-In Sockets ensure reliable IC performance in demanding test environments.

As a semiconductor professional, you recognize the essential role burn-in sockets play in integrated circuit (IC) testing. The QN Series Burn-in Socket by Smiths Interconnect stands as a pivotal innovation, offering unparalleled reliability and performance.

This article delves into the significance of these solutions, highlighting their contribution to high-reliability testing. Furthermore, as SEMICON Southeast Asia (SEA) 2025 approaches, the industry’s attention turns to the latest developments and exhibitions.

Discover how the QN Series can improve your testing processes and ensure the durability and performance of your ICs.

Scalable Burn-In Socket Solutions for High-Reliability IC Testing

Burn-In Testing Challenges and Solutions

In today’s fast-changing IC industry, reliable burn-in testing is critical. Smiths Interconnect’s QN Series Burn-In Sockets are built to meet the high demands of modern IC testing. Designed to operate up to 150°C, they’re ideal for next-gen microcontrollers and automotive-grade components.

Advanced Design Features

The QN Series stands out with high socket density to save board space without compromising performance. Copper heat slugs boost thermal management, while low inductance and contact resistance deliver excellent signal integrity.

Modular configurations add flexibility, making setup easier and adaptable to different testing needs. These features make the QN Series a go-to choice for engineers focused on reliable, efficient IC testing.

How the QN Series Enhances Burn-In Testing Performance

Burn In Test Socket

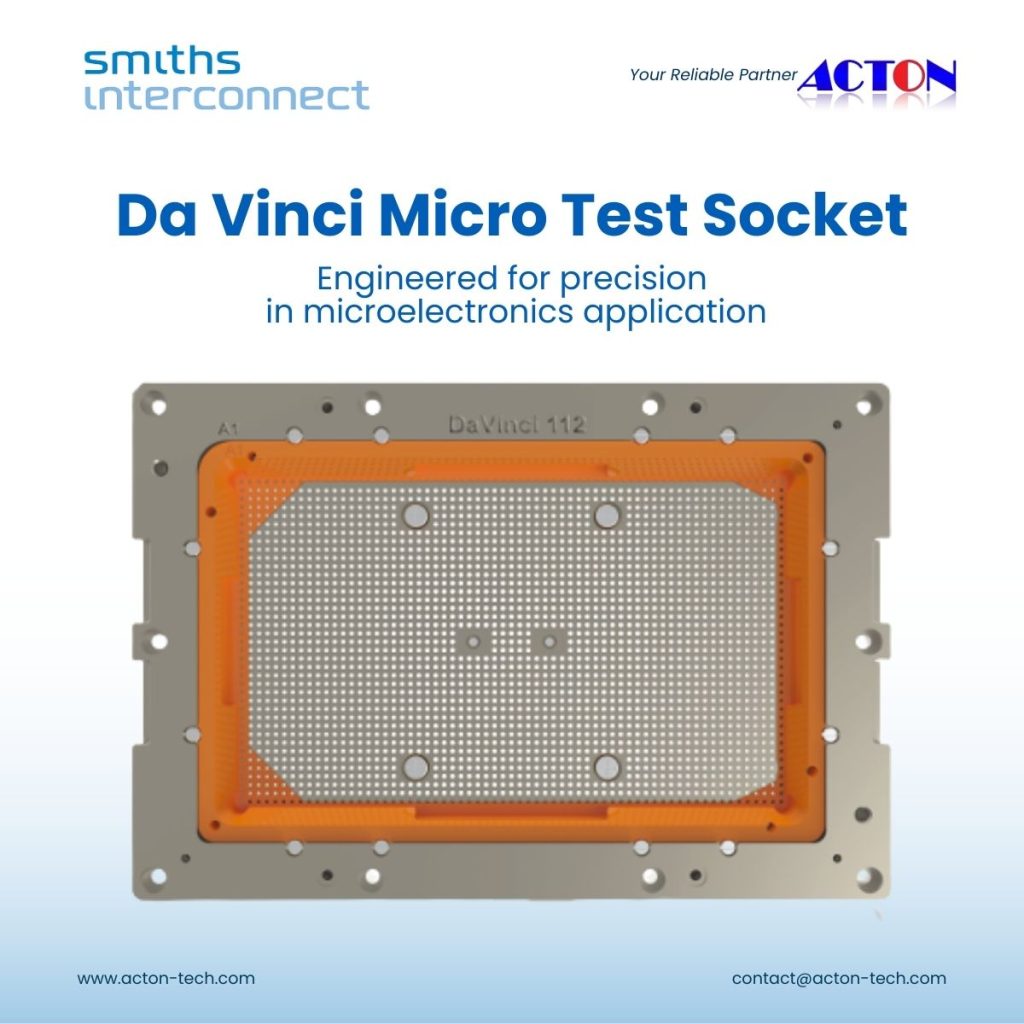

Micro Test Socket

Burn In Testing

Enhanced Thermal Management

The QN Series Burn-In Sockets deliver high-reliability testing and use copper heat slugs for superior thermal management.

This feature ensures efficient heat dissipation, maintaining optimal operating temperatures up to 150°C. Such capability is crucial in preventing overheating, thereby enhancing the longevity and integrity of the integrated circuits.

Superior Signal Integrity

Designed with low inductance and contact resistance, the QN Series ensures intact signal integrity during burn in testing.

This is essential for maintaining accurate test results, especially when qualifying next-generation microcontrollers or conducting automotive-grade reliability assessments. The exclusive H-Pin® technology further reduces electrical noise, enabling precise data collection.

Space-Saving Design

With high socket density, the QN Series conserves precious board space, allowing for more efficient test setups.

This compact design does not compromise performance, providing flexibility in various testing environments. Whether in R&D labs or during mass production, the modular configurations facilitate rapid deployment, streamlining the testing process.

Smiths Interconnect: Advancing Burn-In Socket Technology for Next-Gen Semiconductors

Leading Innovation in IC Testing

Smiths Interconnect leads innovation in burn-in socket technology, focusing on next-generation semiconductors. The QN Series Burn-In Sockets exemplify this commitment by addressing key industry challenges. Operating up to 150°C and featuring unique H-Pin® technology, they deliver exceptional thermal management and signal integrity.

Improving Reliability and Efficiency

For semiconductor professionals and engineers, the reliability and efficiency of testing equipment are non-negotiable.

The QN Series offers modular configurations for fast deployment, making testing efficient and precise. Whether conducting burn in testing for microcontrollers or automotive-grade reliability tests, Smiths Interconnect’s solutions ensure cutting-edge performance.

Witness Cutting-Edge Innovation

Experience firsthand the groundbreaking QN Series Burn In Sockets at SEMICON SEA 2025. This prestigious event provides a unique opportunity to observe the superior performance and reliability that these sockets bring to semiconductor testing. As a professional in the field, you’ll gain valuable insights into how the QN Series enhances testing with advanced H-Pin® technology and superior thermal management.

Engage with Experts

Engage with industry-leading experts and delve deeply into the nuances of burn in testing. Explore how the QN Series’ modular configurations and high socket density can streamline your operations. This engagement will expand your knowledge and empower you to advance the limits of IC testing solutions.

services

Acton Technology: Your Local Partner for Scalable Test Solutions

Reliable Partnership

Acton Technology stands as your reliable partner in delivering scalable test solutions tailored for the semiconductor industry. Known for its innovation and precision, Acton Technology supports your testing needs with efficiency and expertise.

Comprehensive Testing Solutions

With the QN Series Burn In Socket, Smiths Interconnect addresses critical pain points in IC testing. These solutions handle high temperatures, optimize board space, and maintain signal integrity—key factors in burn-in testing. Copper heat slugs and modular designs further boost performance, making the sockets ideal for various testing environments.

Commitment to Excellence

By partnering with Acton Technology, you receive local support and access to cutting-edge technology, ensuring your testing processes remain effective and future-ready.