Specifications are for reference only and may vary based on product customization.

Your Reliable Partner

Acton Technology is a trusted regional distributor of OMRON industrial automation components across Asia‑Pacific and Southeast Asia (including Singapore, Malaysia, Indonesia, Thailand, Vietnam, and the Philippines).

Reliable Automation Partner Across the Region

Manufacturers, system integrators, and engineering teams rely on Acton for access to OMRON relays, sensors, power supplies, control systems, safety devices, and industrial automation solutions. Acton provides steady inventory, optimized logistics, and local technical support to help reduce lead times and maintain production efficiency.

OMRON Supplier for Full Product Coverage

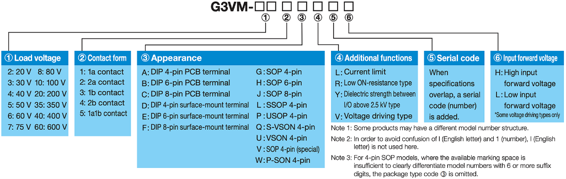

OMRON MOS FET Relays - Acton as Omron Supplier

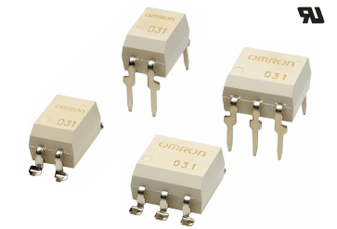

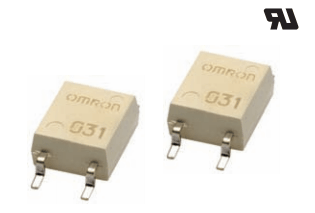

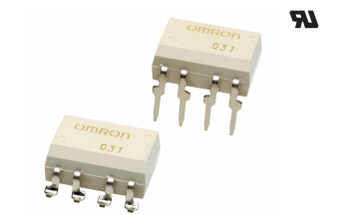

Acton Technology supplies a wide range of OMRON MOS FET relays—non-contact, semiconductor-based switching solutions designed for high-speed and low-leakage performance. These relays combine the functional benefits of mechanical relays and solid-state components, making them ideal for compact and high-reliability applications.

LINE UP

General Purpose Types

High-demand components ideal for switching small and analog signals. Their versatility makes them a preferred solution across a wide range of precision applications.

High Load Voltage Types

Experience high-load voltage performance in a compact SOP4 package—powered by advanced MOS FET relay technology.

Multi Contact Pair Types (2a/2b/1a1b)

Discover MOS FET relays with flexible multi-pole contact options (2a/2b/1a1b), designed for seamless integration into diverse circuit designs.

High Current Low on Resistance Types

Experience MOS FET relays with low on-resistance and high-capacity switching—delivering performance comparable to traditional mechanical relays.

Small High Dielectric Strength Types

Achieve a substantial 5,000 VAC input-output isolation in a compact DIP4 package. High-sensitivity models are also available for applications requiring enhanced precision.

High Dielectric Strength Types

MOS FET relays featuring 5,000 VAC input-output isolation, enabled by a compact DIP6 pin package.

Current Limiting Types

Experience MOS FET relays with built-in current limiting—an ideal choice for protecting circuits against overcurrent conditions.

Low Capacity Between Terminals Low on Resistance Types

Explore our Low CxR MOS FET relays, engineered for semiconductor test applications. These models minimize capacitance and on-resistance (C×R) to deliver superior switching precision and signal integrity.

Small High Load Voltage Types

MOS FET relays delivering high load voltage in a compact, subminiature package—ideal for space-constrained designs.

Small Size High Current Types

MOS FET relays designed for high current switching in a compact, subminiature package—perfect for dense circuit layouts.

Voltage Driving Types

Voltage-driven MOS FET relays featuring a built-in input-side current limiting resistor for added circuit protection and stability.

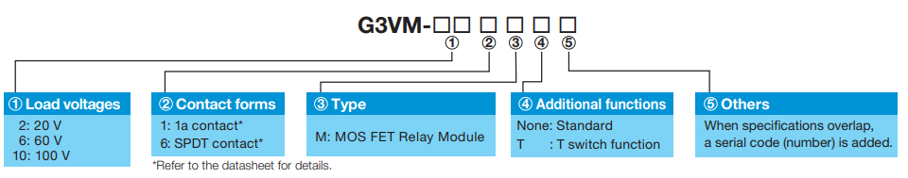

MOS FET Relay Module

MOS FET relay in a modular SPDT (1C) package, featuring ultra-low leakage current—just 1 pA max—for high-precision applications.

Industries rely on OMRON MOS FET relays for:

- Semiconductor inspection systems

- Precision test and measurement equipment

- Security and surveillance devices

- Medical instruments and industrial control systems

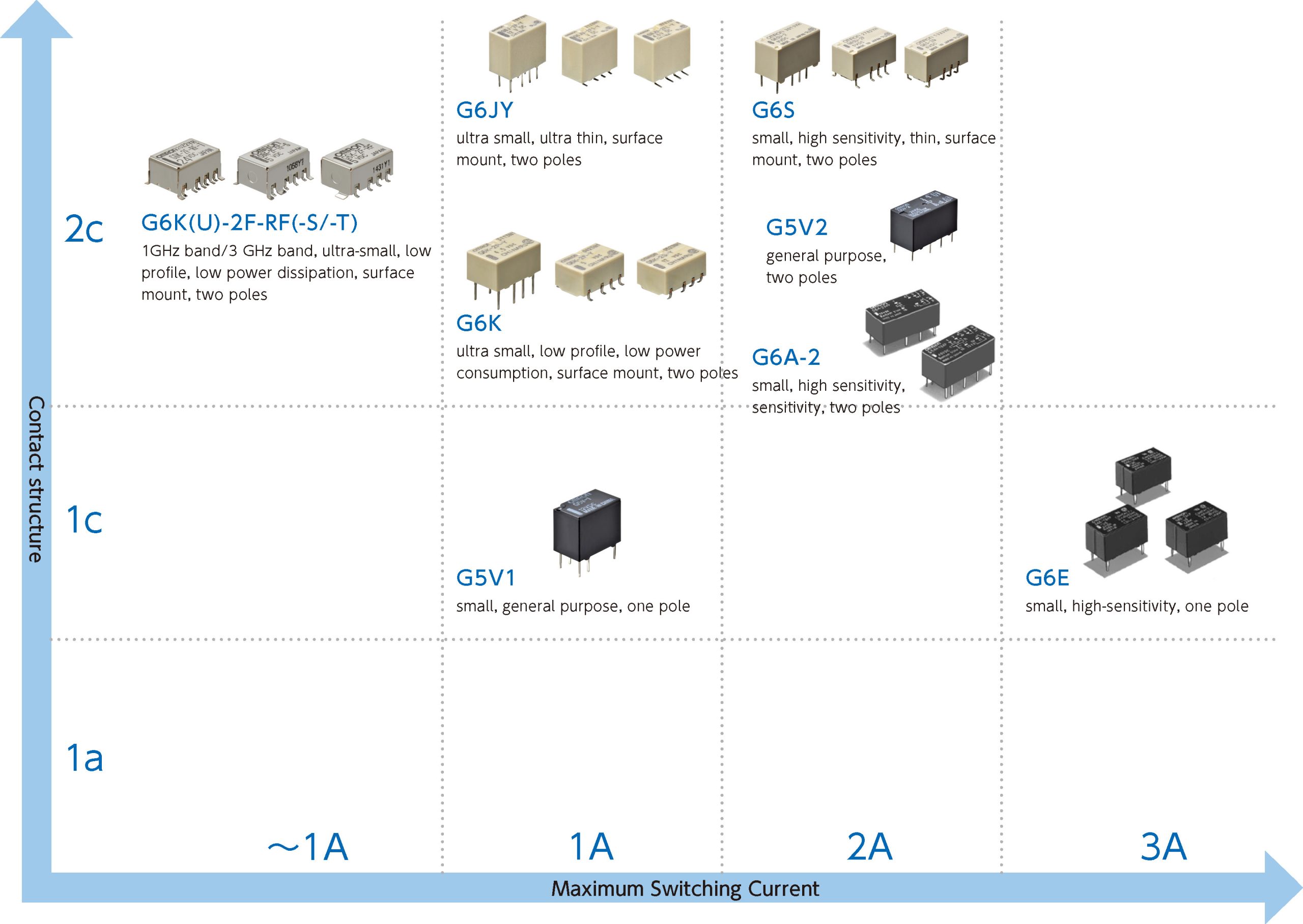

OMRON Signal Relays - Acton as Omron Supplier

Acton Technology supplies OMRON signal relays for compact, high-precision switching of small signals. Built for reliability and low power consumption, these relays are used in communication systems, test equipment, and control circuits where space and performance matter.

LINE UP

G5V-1

Compact, High-Sensitivity SPDT Signal Relay for Space-Constrained Designs

G5V-2

Cost-Effective, Two-Pole Signal Relays for General-Purpose Use

G6A

Proven Global Standard – OMRON G6A Signal Relay

G6E

Subminiature SPDT Relay for Sensitive Signal Switching

G6J-Y

Ultra-Compact, Slim DPDT Relay for Space-Saving Designs

G6K

Surface-Mount Relay with Industry-Leading Compact Footprint

G6K(U)-2F(P)-RF(-S,-T)

Global Standard ISO Plug-in Relays for Automotive Applications

G6K-2F-RF-V

8 GHz Miniature DPDT Relay for High-Speed Differential Signal Switching

G6S

Compact 2-Pole Relay Designed for 2A Signal Load Switching

Industries rely on OMRON signal relays for:

- Security systems – detectors, control panels, and monitoring equipment

- Test and measurement devices – oscilloscopes, IC testers, and inspection tools

- Industrial automation – machine tools, molding machines, welders, and robotic systems

- Amusement equipment – gaming machines and peripheral control systems

PCB Power Relays - Acton as Omron Supplier

Acton Technology supplies OMRON PCB power relays designed for high-capacity load switching in compact circuit designs. Engineered with arc-resistant contact materials and a single contact structure, these relays ensure stable performance in power supply systems. Ideal for applications requiring reliable contact pressure and compliance with key safety standards.

LINE UP

PCB Power Relays

High-capacity PCB power relays for reliable switching in compact systems.

DC small power relay

DC miniature power relays for reliable load interruption at 12V and 24V.

Power Relays High Capacities Switching

DC power relays for high-voltage, high-current load interruption in DC systems.

AC Power Latching Relays

Latching relays with high switching current for versatile application use.

Industries rely on OMRON latching relays for:

- Industrial equipment – machine tools, molders, welders, mounters, and robotic systems

- Power supply systems – UPS units, switching power supplies, and backup systems

- Factory automation – PLCs, temperature controllers, timers, and I/O devices

- Home appliances – air conditioners, refrigerators, washing machines, and more

- Energy infrastructure – PV inverters, EV chargers, and industrial air conditioning systems

OMRON Switches - Acton as Omron Supplier

Acton Technology supplies a wide portfolio of OMRON switches designed for precision, reliability, and long service life. Our range covers solutions for control, detection, and safety applications across industrial, automotive, and consumer electronics. From basic and detection switches to specialized models, we deliver components that ensure dependable performance and accurate actuation in any operating environment.

Basic Switches

LINE UP

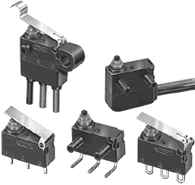

Miniature Basics Switches (V-Size)

Miniature Basic Switches 27.8W×10.3D×15.9H: Compact, durable switches that provide precise and reliable operation in limited‑space applications.

Subminiature Basic Switches (S-Size)

Subminiature Basic Switches 19.8W×6.4D×10.2H: Ultra‑compact switches engineered for precise, reliable performance in tight‑space applications. Ideal for miniaturized devices and high‑density assemblies.

Ultra Subminiature Basic Switches (J-Size)

Ultra Subminiature Basic Switches – 12.8W × 5.8D × 6.5H: Extremely compact switches designed for high‑precision, reliable performance in the smallest spaces. Perfect for miniaturized devices and dense electronic assemblies.

Sealed Basic Switches

Sealed switch against water spray or excessive dust: Protected against water spray and excessive dust for reliable performance in harsh or contaminated environments.

Applications:

- Automatic Doors and Gates

- Arcade Controllers

- Machine Tools

- Electric Locks

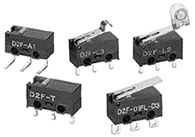

Detection Switches

LINE UP

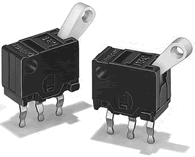

Detection Switches

General purpose detection switches: Versatile switches designed for accurate and reliable detection in a wide range of applications.

Surface Mount Detection Switches

Ultra subminiature SMD detection switches: Space‑saving surface‑mount switches engineered for precise, reliable detection in compact electronic devices.

Applications:

- Electric Locks

- Machine Tools

- Elevator

- Smart Switches for Lighting

- Mouse

- Arcade Controllers

- Transceiver

- Industrial Robots

- Machine Tools

- Temperature Controllers and PLCs

- Gaming controllers

Door Switches/Power Switches

LINE UP

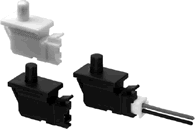

Miniature Door Switches

Switches to detect door open/close: Reliable switches designed to accurately detect door open and close positions for safety and control applications.

Power/Door Switches

Switches to detect door open/close and to cut the power supply of industrial equipment: Switches designed to detect door open/close status and automatically cut power to industrial equipment for safety and compliance.

Applications:

- Electric Locks

- Machine Tools

Tactile Switches

LINE UP

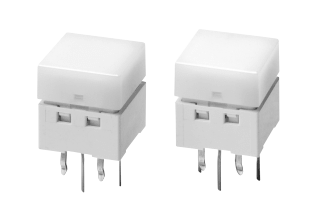

Standard Types

Tactile switches for various operation panel: Compact, responsive switches designed for precise input and reliable performance in a wide range of operation paels.

Illuminated Types

Compact construction with bright and uniform illumination: Space‑saving design featuring bright, even lighting for clear visibility and enhanced user interaction.

Sealed Types

Dust proof tactile switch by sealed construction: Sealed construction prevents dust ingress, ensuring reliable performance and long service life in demanding environments.

SMD Types

SMD tactile switch suitable for high density mounting: Surface‑mount design optimized for high‑density PCB layouts, delivering precise actuation in compact electronic assemblies.

Hinged Types

Hinged design developed through ergonomics: Hinged mechanism engineered for comfortable, intuitive operation based on ergonomic principles.

Key tops for Tactile switches

Key tops for B3F, B3W and B3FS: Durable, precisely‑fitted key tops designed to enhance operation and compatibility with OMRON B3F, B3W, and B3FS switches.

Applications:

- Mouse

- Temperature Controllers and PLCs

Rocker Switches

LINE UP

A8GS

Minimum size class in the industry Rocker switch with reset function: Space‑saving rocker switch designed for reliable control, featuring an integrated reset function for enhanced safety and convenience.

A8GS-T

Minimum size class in the industry Remote Reset Rocker Switch with Delay OFF Function: Compact rocker switch with remote reset capability and delay‑OFF function for precise control and added operational safety in space‑limited applications.

A8L

Miniature Rocker Switch for High Capacity Switching: Compact design engineered to handle high‑capacity loads, delivering reliable performance in demanding applications.

A8G

Rocker Switch with External Reset Function for High capacity Switching: Durable rocker switch designed for heavy‑load applications, featuring an external reset function for enhanced safety and control.

A8A

Safety-considered Power Rocker Switch: Engineered with safety features to ensure reliable power control and prevent accidental operation in critical applications.

Applications:

- Elevator

- Industrial Robots

Pushbutton Switches /Indicators

LINE UP

Small Pushbutton Switches/Small Indicator

Small pushbutton switches and indicators with 8 to 12mm diameter: Compact pushbuttons and indicators designed for precise operation and clear signaling in space‑restricted panels and devices.

Pushbutton Hand switches

Pushbutton Hand switch: Hand‑operated switch designed for quick, reliable control in various equipment and machinery applications.

Applications:

- Industrial Robots

Toggle/Pushbutton Switches

LINE UP

Toggle Switches

Ultra subminiature toggle switches: Exceptionally compact toggle switches engineered for precise, reliable control in space‑constrained electronic applications.

Pushbutton Switches

Ultra subminiature pushbutton switches: Extremely compact pushbutton switches designed for accurate operation and dependable performance in tight‑space applications.

Applications:

- Industrial Robots

Toggle/Pushbutton Switches

LINE UP

Slide Types

DIP switch for various setting devices: Compact and reliable switch solution for precise configuration and easy setting adjustments in electronic equipment.

Piano Types

DIP switch with up and down operation: Space‑efficient switch designed for intuitive up/down control, enabling quick and accurate settings in electronic devices.

Rotary Types

Rotary DIP switch suitable for channel setting: Durable, precise rotary switch designed for accurate channel selection and reliable performance in communication and control equipment.

Applications:

- Commercial Air Conditioning

- Security Devices

- Servo Inverter

- Temperature Controllers and PLCs

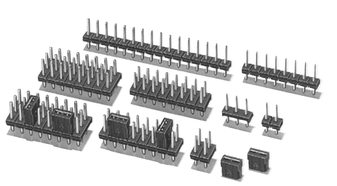

OMRON Connectors - Acton as Omron Supplier

Acton Technology supplies OMRON connectors for secure, reliable, high‑performance connections. Our portfolio includes PCB, board‑to‑board, board‑to‑FPC, external, and industrial connectors, from compact designs to rugged MIL‑standard models, ensuring dependable signal and power transmission in industrial, automotive, and consumer electronics.

Board to Cable Connectors

LINE UP

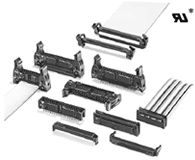

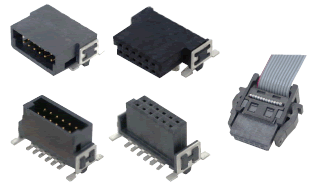

Flat Cable Connectors

Durable, high‑precision connectors designed for secure and efficient flat cable connections in PCB and MIL‑standard applications.

Crimped MIL Connector Sockets for Discrete Wires

High‑reliability crimped sockets designed for discrete wires, fully compatible with the MIL connector series for secure and durable connections.

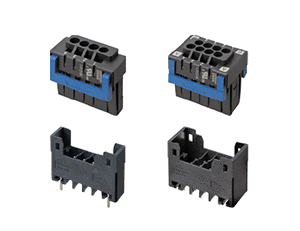

Easy-wire Connectors for Industrial Components

e‑CON specification connectors designed for quick, reliable wiring—ideal for connecting sensors in industrial applications.

Half-Pitch SMT Connectors

Compact, surface‑mount connectors with a 1.27 mm pitch for reliable, space‑saving PCB connections.

PCB Terminal Blocks

Reliable terminal block connectors designed for secure controller interface connections on PCBs.

Applications:

- PV invertor

- Energy storage system

- EV charger

- Robot controller

- Servo controller Stepping controller

- Working machine Forming machine

- Semiconductor manufacturing equipment

- Financial machine

- Home appliances/ small home appliances

- Building/home security devices

Board to Board Connections

LINE UP

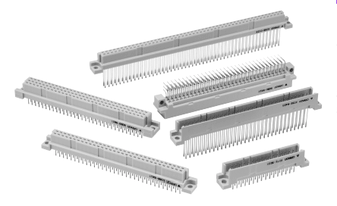

DIN Connectors/DIN Style Connectors

Comprehensive range of connectors built to international DIN standards, ensuring reliable, standardized board‑to‑board connections.

Half-Pitch SMT Connectors

Surface‑mount connectors with a 1.27 mm contact pitch, supporting 1 mm increments for stacking heights from 5 mm to 20 mm.

Applications:

- PV invertor

- Energy storage system

- EV charger

- Robot controller

- Servo controller Stepping controller

- Working machine Forming machine

- Semiconductor manufacturing equipment

- Financial machine

- Home appliances/ small home appliances

- Building/home security devices

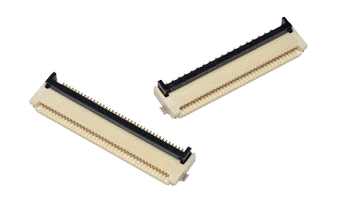

FPC/FFC Connectors

LINE UP

XF3M / XF2M Rotary Backlock Connectors

Rotary Backlock connectors (0.5 mm and 1.0 mm pitch) with dual‑sided or upper‑sided contacts, designed for easier FPC/FFC cable insertion and a secure “sure‑lock” connection feel.

Applications:

- PV invertor

- Energy storage system

- EV charger

- Robot controller

- Servo controller Stepping controller

- Working machine Forming machine

- Semiconductor manufacturing equipment

- Financial machine

- Home appliances/ small home appliances

- Building/home security devices

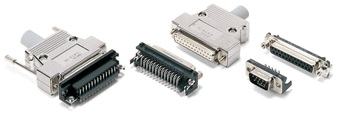

External Connector

LINE UP

D-Sub Connectors

Durable connectors designed for reliable office equipment interfaces and secure external connections.

USB Connectors

USB‑compliant connectors designed for reliable, high‑speed data and power transmission.

Applications:

- PV invertor

- Energy storage system

- EV charger

- Robot controller

- Servo controller Stepping controller

- Working machine Forming machine

- Semiconductor manufacturing equipment

- Financial machine

- Home appliances/ small home appliances

- Building/home security devices

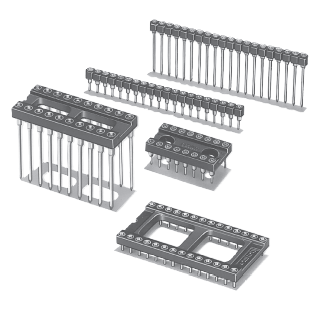

IC Sockets/Jumper Plugs

LINE UP

IC Sockets

High‑reliability IC connectors designed to maintain stable performance and tolerate momentary power interruptions.

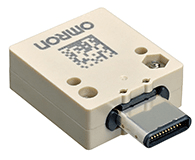

Testing Socket for Devices with USB Type C Connector

Precision socket designed for reliable testing of electronic devices with a USB Type‑C I/O connector.

Jumper Plugs

Low‑profile circuit jumper connectors designed for quick, reliable PCB connections.

Applications:

- PV invertor

- Energy storage system

- EV charger

- Robot controller

- Servo controller Stepping controller

- Working machine Forming machine

- Semiconductor manufacturing equipment

- Financial machine

- Home appliances/ small home appliances

- Building/home security devices

OMRON Sensors - Acton as Omron Supplier

Acton Technology offers OMRON sensors for accurate, reliable detection in industrial, automotive, and consumer electronics. Our lineup includes flow, pressure, vibration, thermal, image, displacement, IoT, and optical sensors, providing precise monitoring, improved safety, and enhanced performance.

Flow Sensors

LINE UP

Mems Flow Sensors (Flow Rate Types)

High‑accuracy sensors designed for precise flow measurement across a wide range of applications, offering reliable performance and versatile capabilities.

Mems Flow Sensors (Velocity Types)

Airflow sensing solutions designed for precise air conditioning control, delivering energy efficiency and consistent performance without compromising quality.

Applications:

- Combustion

- HVAC

- Measurement

- Clogging Detection

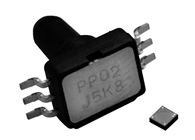

Pressure Sensors

LINE UP

MEMS Gauge Pressure Sensors

Subminiature sensors engineered for accurate gauge pressure measurement with low power consumption.

Applications:

- Combustion

- HVAC

- Measurement

- Clogging Detection

Vibration Sensors/Tilt Sensors

LINE UP

Seismic Sensors

World’s smallest class of high‑precision seismic sensors, designed for accurate detection and IoT integration.

Vibration Sensors/Tilt Sensors

Quickly detect vibration or tilt caused by earthquakes, enabling timely action to prevent secondary disasters.

Automatic Horizontal Vibration Sensors

Rapidly detect earthquakes to help prevent secondary disasters, featuring an auto‑level mechanism for mounting tolerance of ±5°.

Applications:

- Industrial (Semiconductors/FPDs, machine tools, control panels, combustion furnaces, printers)

- Residential (Distribution boards, disaster prevention systems, home appliances (heaters, gas stoves))

- Commercial (Electrical/gas meters, chemical plants, highways, bridges, tunnels, railroads)

D6T MEMS Thermal Sensors

MEMS Non-Contact Thermal Sensor for Contactless Measurement

Contactless temperature sensors with low NETD achieved through integrated ASIC and MEMS design. Provide direct temperature output for simplified software integration, with options from 1 to 1024 elements and a wide measurement range of ‑40 °C to 200 °C.

Applications:

- Refrigerator Interior & Room Temperature Detection

- Human Presence Detection

- Screening of Humans with Fever

- Abnormal High Temperature Monitoring

Environment Sensors

LINE UP

2JCIE-BL

Compact IoT sensor that measures a variety of environmental parameters for smart monitoring and control.

2JCIE-BU

USB‑type IoT sensor that captures a variety of environmental data for efficient monitoring and management.

Applications:

Six types of sensing functions

Temperature, humidity, light, barometric pressure, noise, acceleration

Photomicrosensors

LINE UP

Transmissive Types

Sensors that detect objects by interrupting a light beam between the emitter and receiver, providing accurate and reliable detection.

Reflective Types

Compact sensors that detect objects by reflecting light from the emitter to the receiver, ideal for space‑constrained applications.

Photomicrosensors for FA

Compact optical sensors designed for accurate workpiece detection in factory automation applications.

Applications:

- Presence detection (Amusement equipment, Robotic vacuum cleaners, Medication related equipment)

- Position detection (Cash dispensers, 3D printers, Commercial coffee machines)

- Rotation detection (Smart gas meters, Mobile IP cameras, Various dials)

- Rotation and direction detection (Robots, Camera lens mechanisms, Analytical equipment (trackball devices))

Light Convergent Reflective Sensors/Diffuse Reflective Sensors

LINE UP

Light Convergent Reflective Sensors

Versatile sensors capable of accurately detecting transparent, mirror, or black targets.

Diffuse Reflective Sensors

Miniature, long‑distance sensors that detect objects by reflected light and can be installed in virtually any location.

Applications:

- Analysis equipment – Container detection

- Printing equipment – Printed paper detection

- Tablet packagers- Tablet package detection

- Coffee makers – Cup detection

- Delivery boxes – Article detection inside boxes

- Sanitation equipment -Hand detection

B5WC Color Sensor to Build into Equipment

NEW Reliable Detection of Changes and Differences in Color – Contributes to Automation of Equipment –

Compact, flexible sensors that detect objects by color to enable stable equipment operation, improve maintenance efficiency, support multifunctionality, and assist in work automation.

Applications:

- Machine tool – Remote monitoring of lubricant color

- Drink dispenser – Automatic supply of beverages according to the cup color

- Object detection on the production line

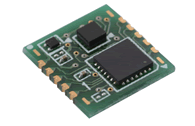

Displacement Sensors/Ranging Sensors

LINE UP

3D TOF Sensors Module

Real‑time 3D sensing module that measures distance to humans or objects with high accuracy for advanced detection and control applications. Ask ChatGPT

Micro-displacement Sensors

Ultra‑compact, high‑resolution sensors ideal for precise measurements such as paper thickness detection.

Applications:

- AMR/ Service robots- Drop detection/ Environment recognition, Periphery recognition/ Human recognition

- Logistics and conveyance- Volume and shape measurement, Empty space detection

- Observation- Behavioral understanding and observation of patients under long-term care

- Automatic doors/elevators- Counting people and tracking traffic flows

Human Detecting Sensors

LINE UP

Human Image Sensors

Image sensing components with 10 integrated functions to detect and interpret human presence and conditions. Ask ChatGPT

Applications:

- Beverage vending machines, ticket vending machines, POS, signage

- Industrial equipment

- Long-distance detection type

Human Image Solution

Applications:

- Digital camera, Smart phone

(Camera App) - Security

IP camera - Digital signage

- Photo management software

- Vending machine

- Communication robot

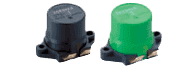

W7ED Touch Sensor

NEW W7ED Touch Sensor

Light‑touch operation for reliable input, with optional anti‑static FG terminal models to prevent static transfer. Compact design allows easy equipment embedding, and touch electrodes can be mounted using simple screw fastening. Supports 5–15 VDC with open‑collector output.

Applications:

- Lights

- Elevators

- Vending Machines

- Faucets

2JCIE-EV Sensor Evaluation Board

2JCIE-EV Sensor Evaluation Board

Development board for quickly creating IoT systems capable of sensing a wide range of environmental parameters.

OMRON EFC Sockets and Pins - Acton as Omron Supplier

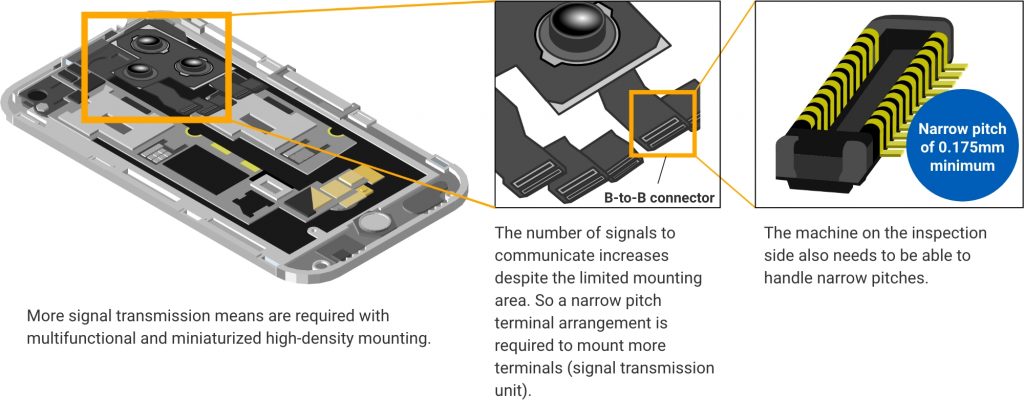

Acton Technology supplies OMRON EFC sockets and blade pins for high‑precision testing of ultra‑compact, high‑density components. The plate‑shaped design supports pitches as narrow as 0.175 mm, delivering durability, accuracy, and reliability for advanced inspection applications.

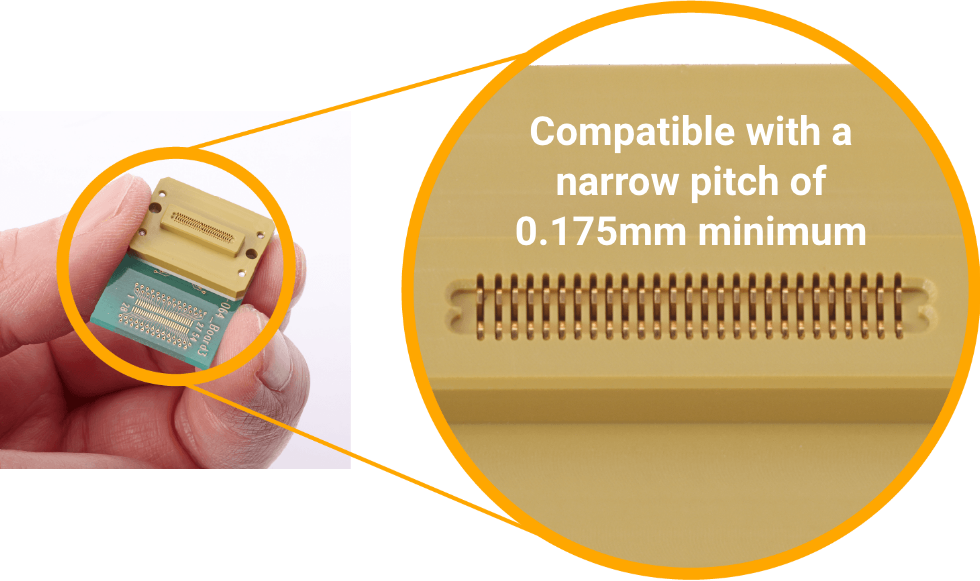

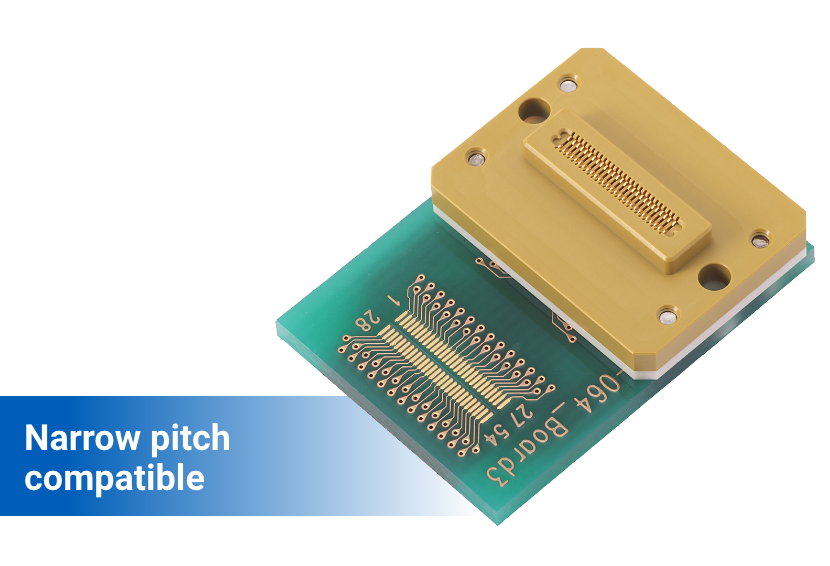

World’s Smallest Class Testing Sockets – 0.175 mm Pitch*

OMRON testing sockets are engineered for high‑precision inspection of today’s ultra‑compact, high‑pin‑count electronic components. Ideal for camera and display modules with dense, narrow‑pitch terminals, these sockets ensure accurate testing and delicate handling even in the smallest form factors.

*Based on OMRON research, March 2023.

Smartphone camera module

World’s smallest class* with a narrow pitch of 0.175mm

*Based on OMRON Research, March 2023

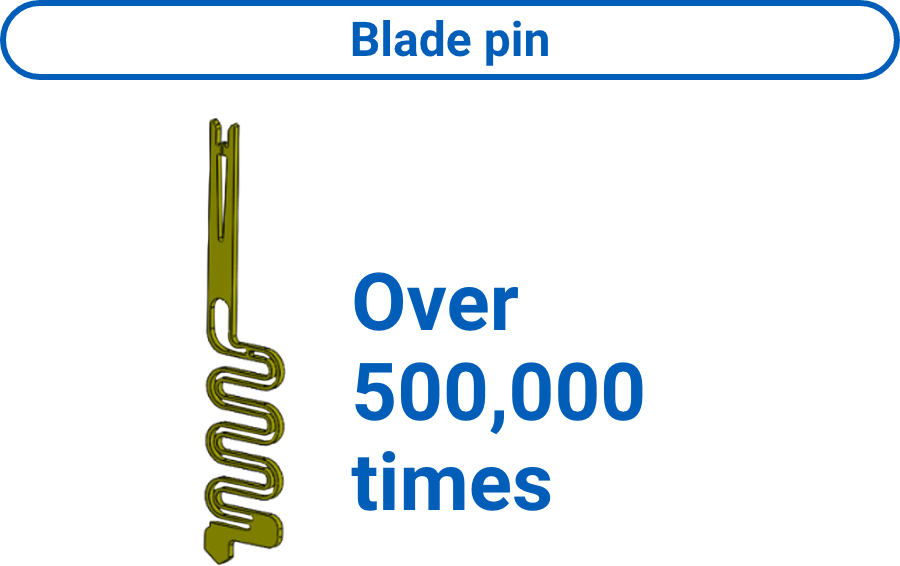

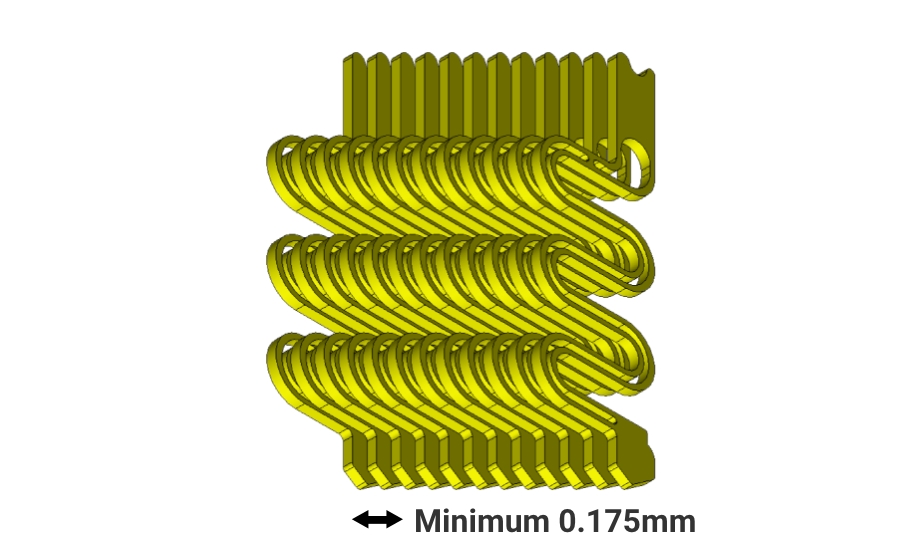

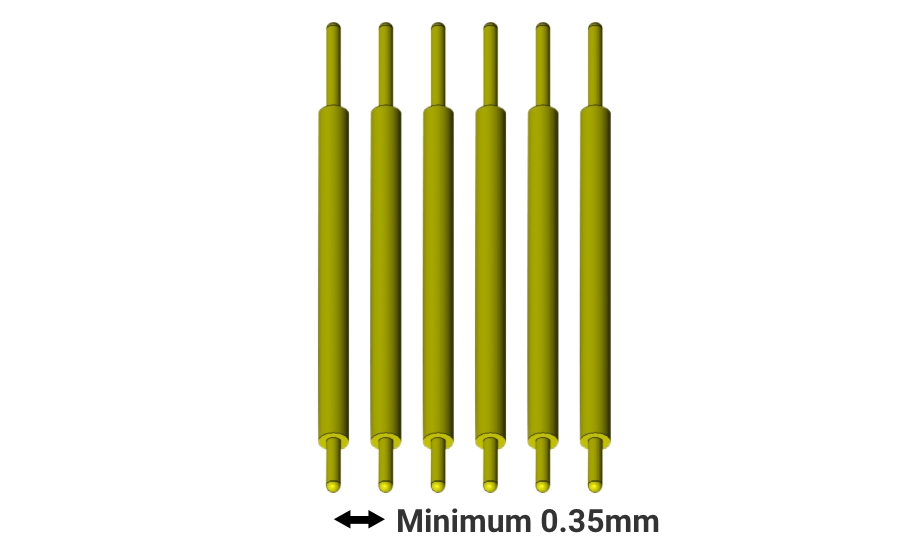

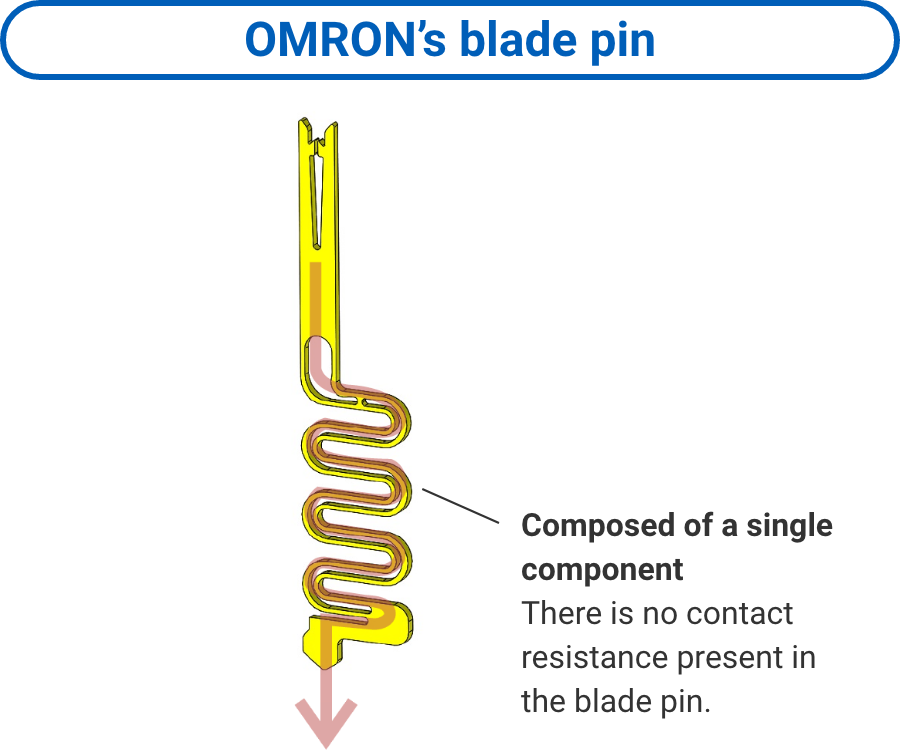

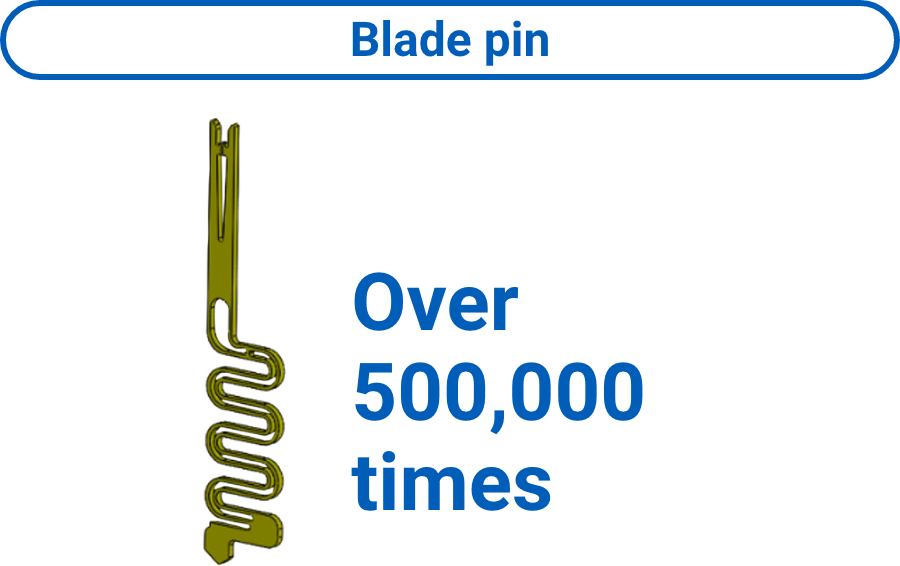

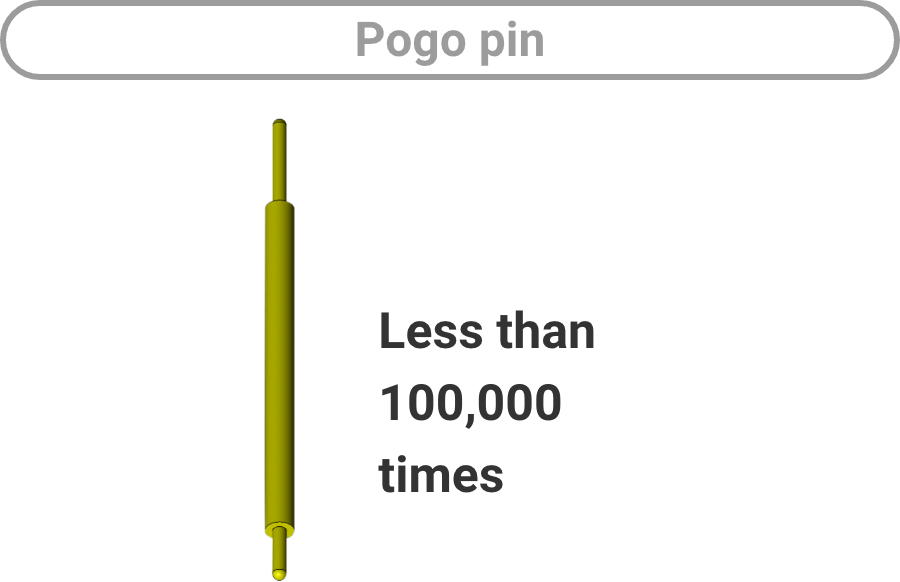

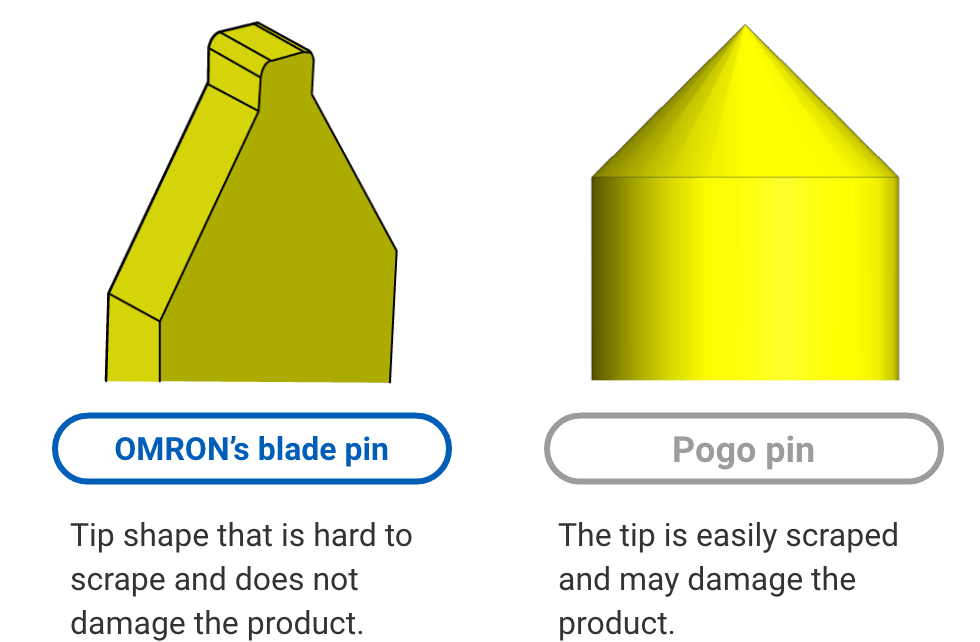

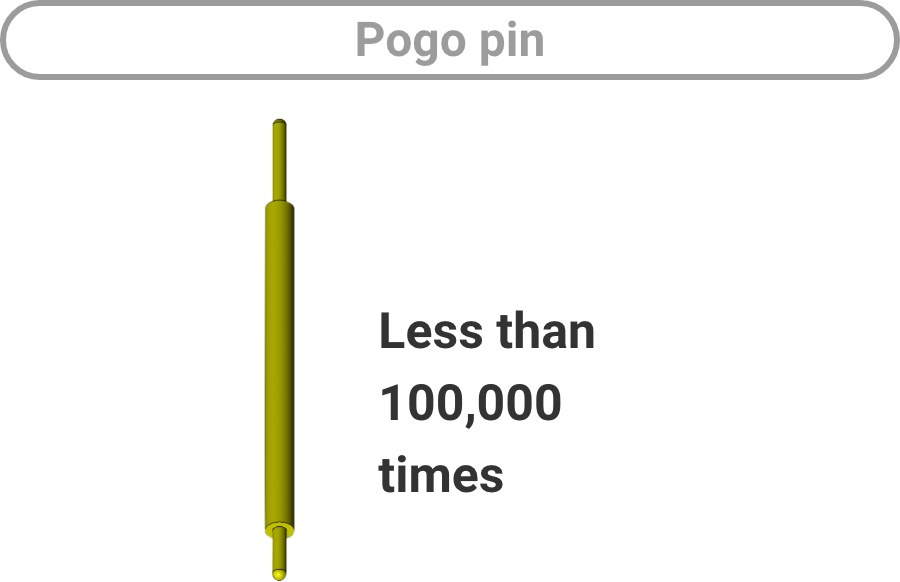

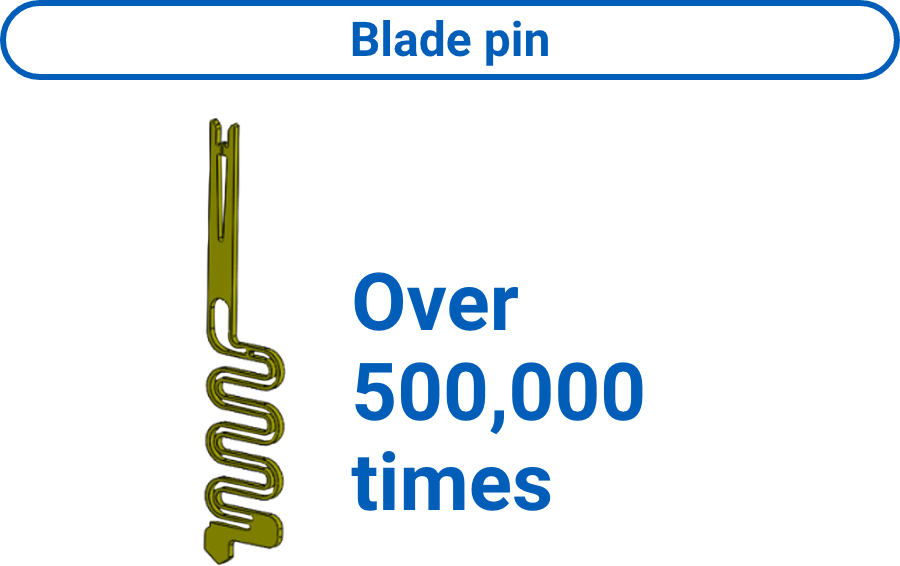

OMRON’s blade pins, made using EFC process technology, enable a minimum pitch of 0.175 mm—far smaller than conventional cylindrical pogo pins—without sacrificing durability. This design meets the narrow‑pitch inspection needs of multifunctional, high‑density mounted products.

OMRON Blade Pin

Plate‑shaped design enables ultra‑narrow pitches down to 0.175 mm for high‑density applications.

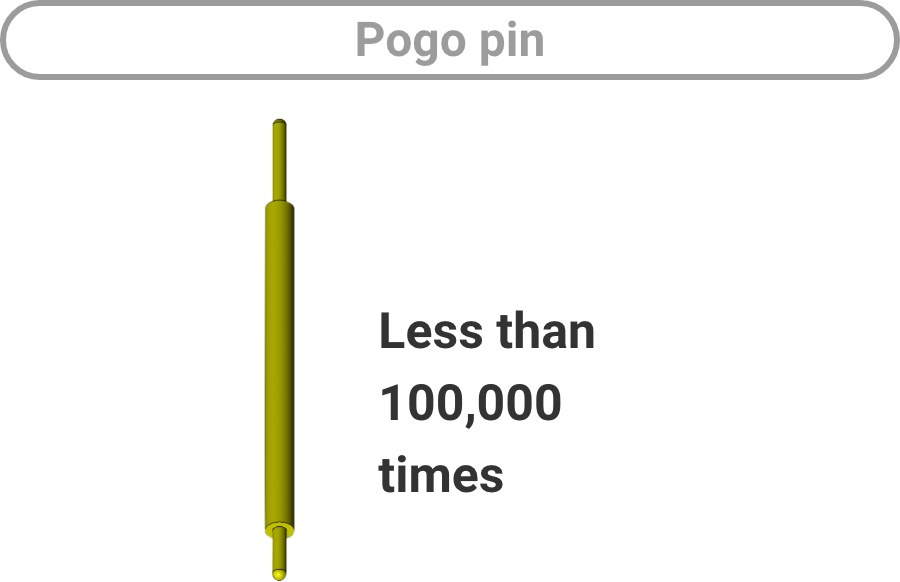

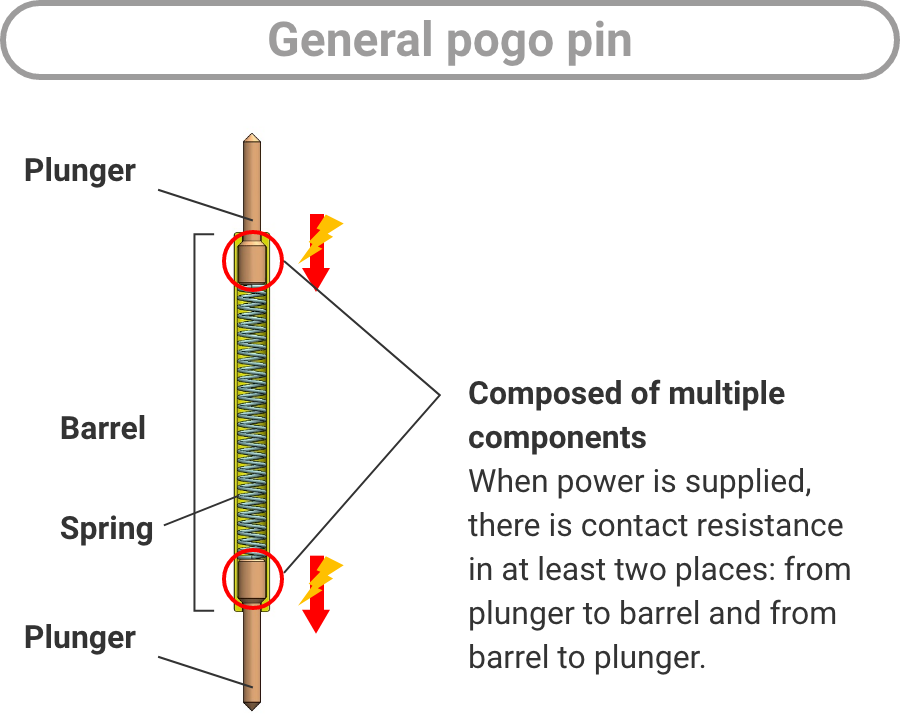

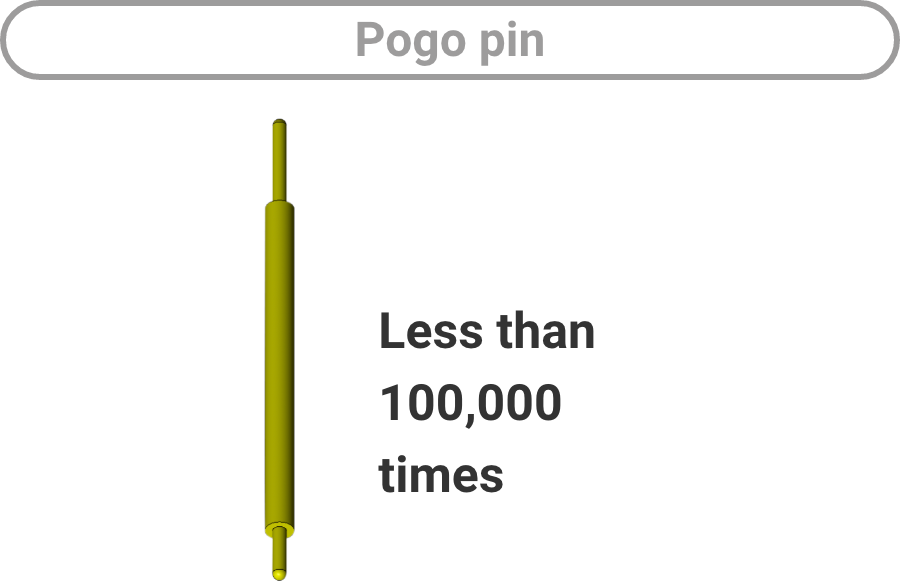

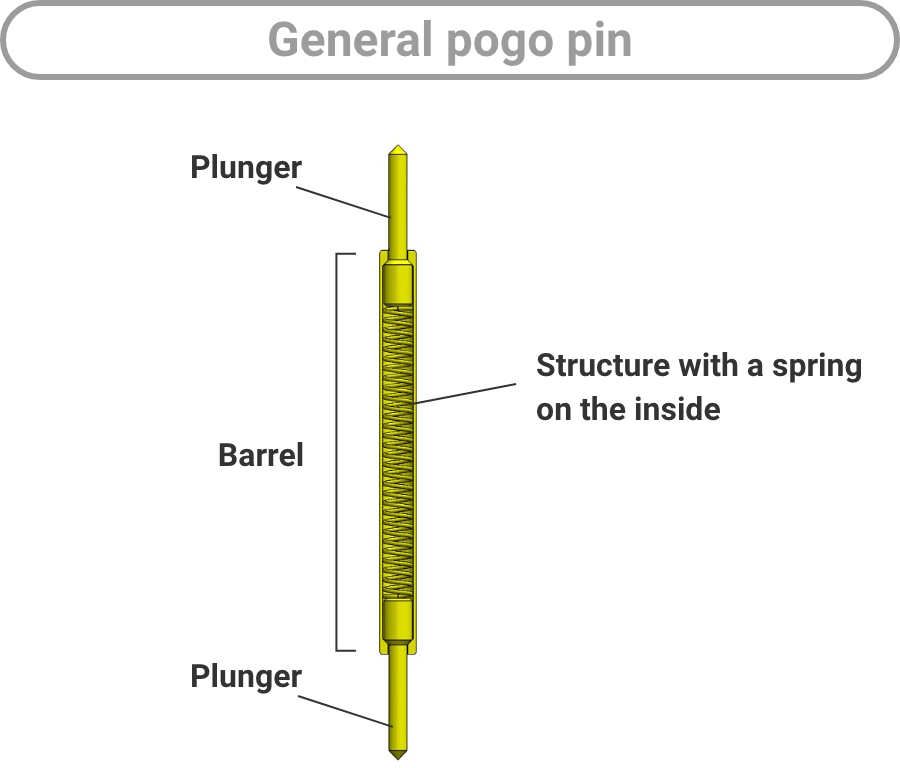

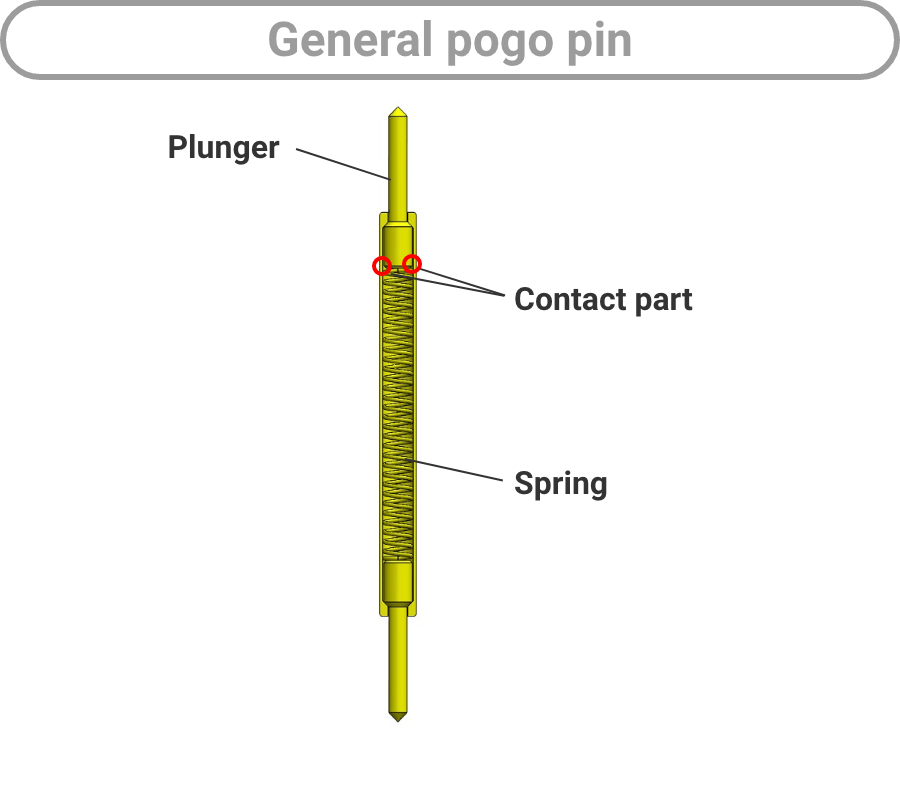

Pogo Pin

Cylindrical design limits pitch to a minimum of 0.35 mm, making it less suitable for ultra‑dense layouts compared to plate‑shaped blade pins.

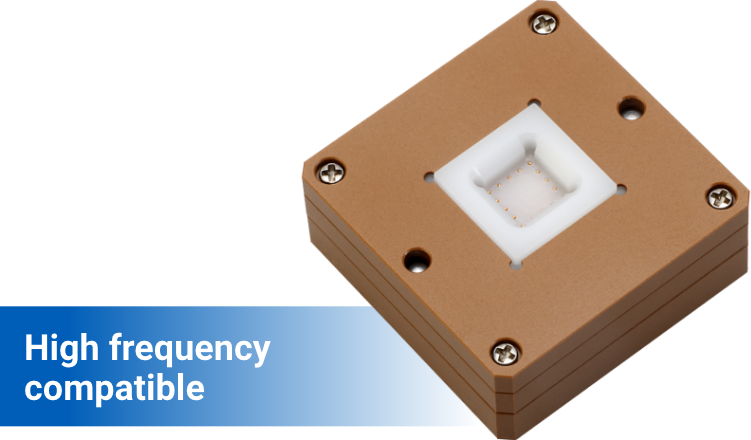

OMRON High‑Frequency Compatible Sockets

Designed for testing high‑frequency circuits in wireless LANs, cellular phones, GPS, and other devices, OMRON sockets support frequencies up to 43.5 GHz. The optimized path length ensures reliable performance with sufficient stroke for accurate inspection.

*Specifications are for reference only and may vary depending on the customized product.

World’s smallest class* with a 0.175 mm narrow pitch

*Based on our research, March 2023.

OMRON High‑Frequency Compatible Sockets

OMRON sockets support up to 43.5 GHz with minimal contact resistance for superior high‑frequency performance. Unlike multi‑part pogo pins, our high‑frequency pins are manufactured as a single component using proprietary EFC process technology, eliminating internal contact resistance and ensuring optimal signal integrity.

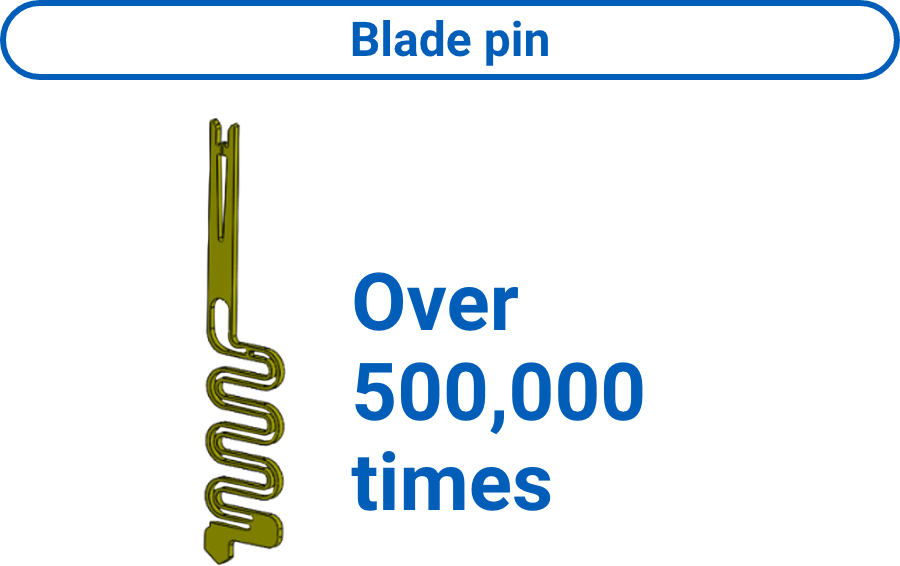

High durability and reduced maintenance

Durable Custom‑Designed Sockets

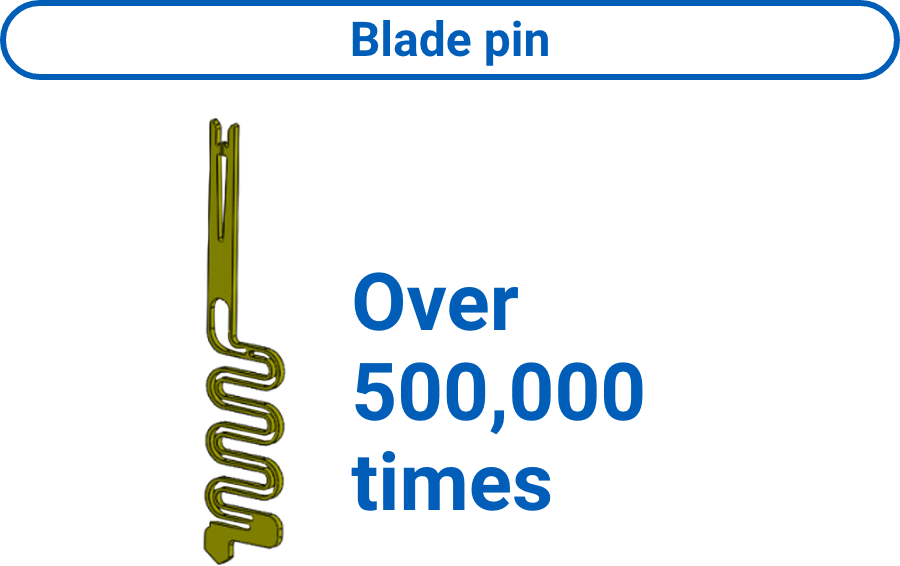

OMRON’s custom design recommendations and patented material blend* make our sockets over five times more durable than pogo‑pin types. This extended lifespan reduces socket replacement frequency, improving efficiency at inspection sites.

*Patent No. 5077479

OMRON High‑Current Compatible Sockets

Built for demanding inspection needs, OMRON high‑current sockets handle 2.5 A DC or more with over 500,000 cycles of mechanical durability. Available in multiple variations, they support a wide range of high‑capacity testing applications.

*Specifications are for reference only and may vary depending on the customized product.

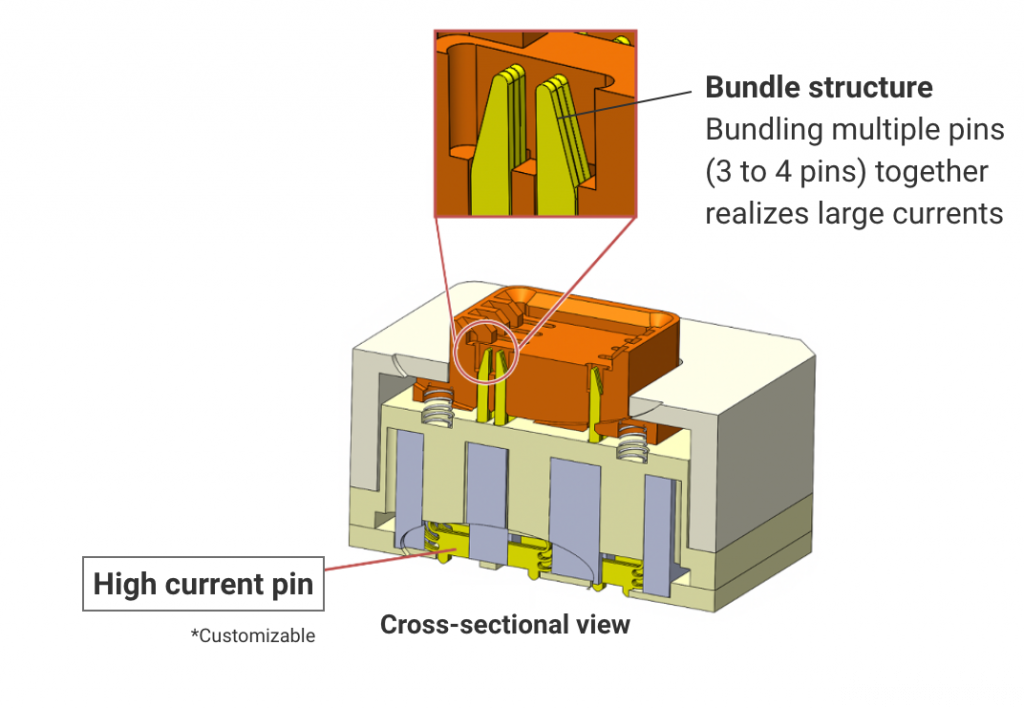

Bundle structure can handle up to 10A DC

OMRON High‑Current Type Sockets

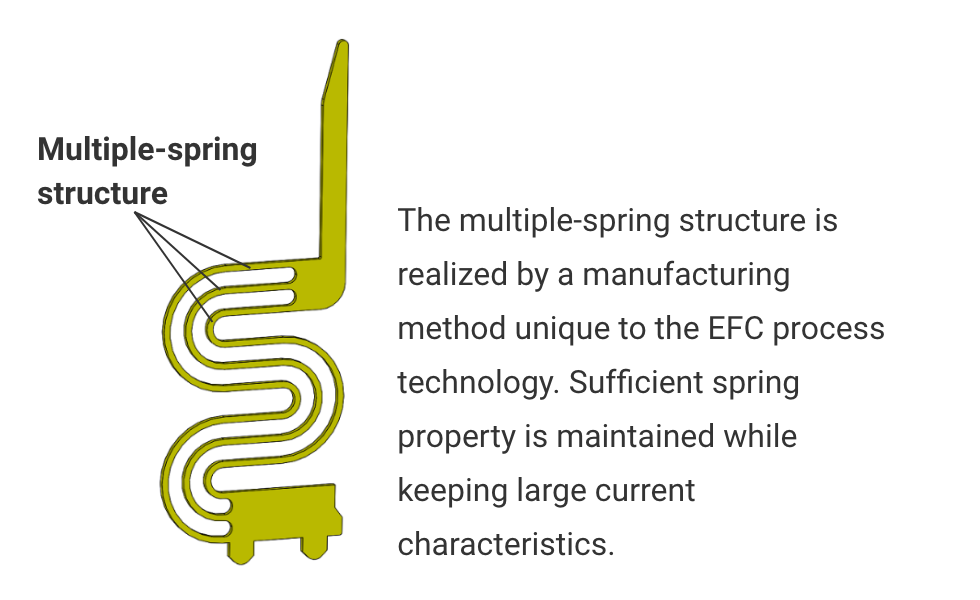

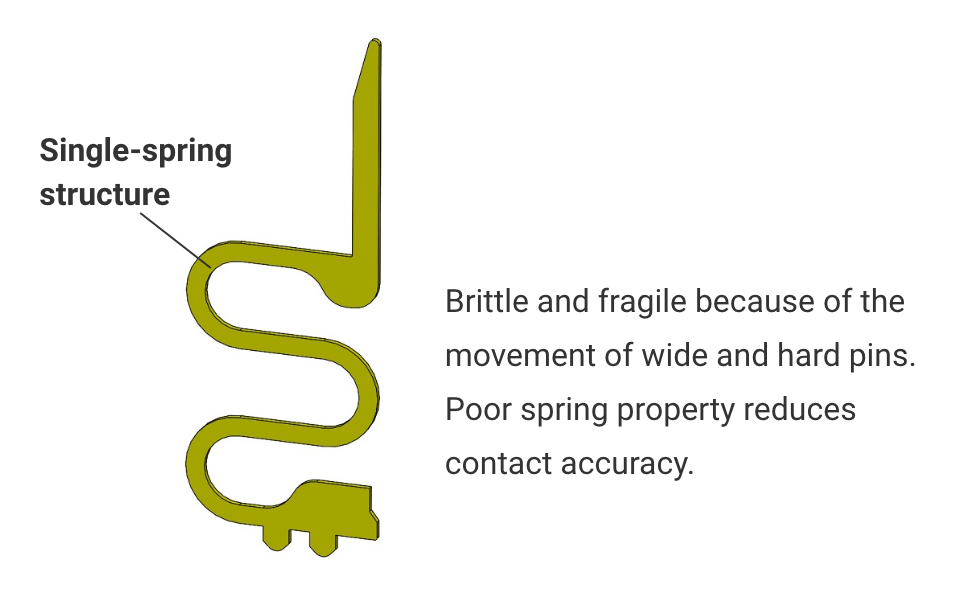

OMRON’s high‑current sockets deliver up to 2.5 A DC per pin or 10 A DC using a bundled multi‑pin structure—ideal for inspecting power semiconductors like QFN packages. Using a unique EFC process, the multiple‑spring design maintains excellent spring properties while handling large currents. This structure ensures accurate contact, durability, and flexible pin movement without sacrificing conduction area.

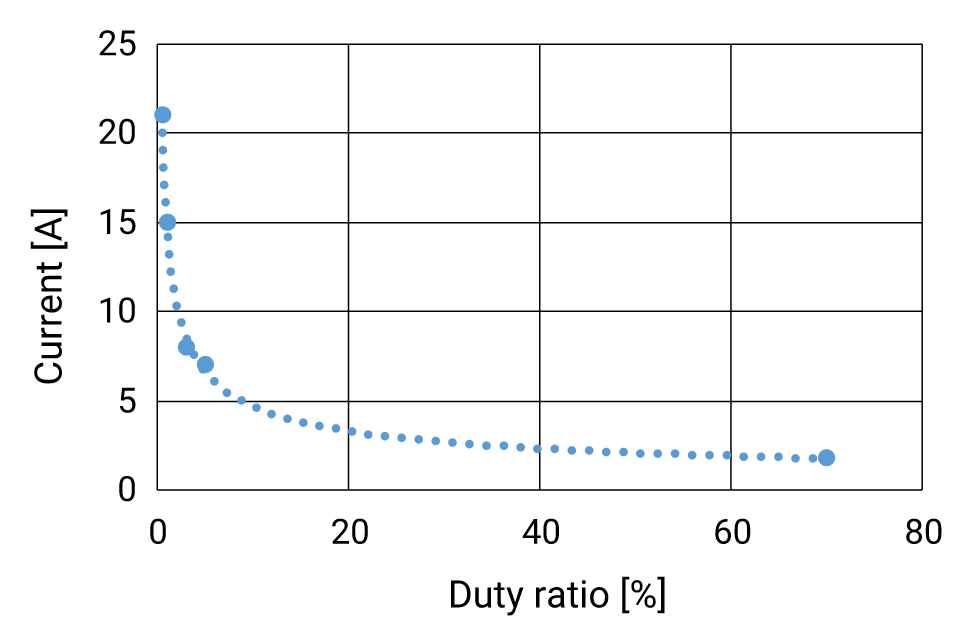

Handling ultra-high current range under low duty ratio (actual value)

High‑Current Socket Performance

OMRON’s high‑current sockets are duty‑ratio tested to ensure reliability. In low duty ratio conditions—where current flows for only short periods—they can handle ultra‑high currents of several tens of amperes, making them ideal for inspecting power semiconductors. Designed for continuity testing rather than sustained high‑current loads, they offer a dependable solution for demanding semiconductor inspections.

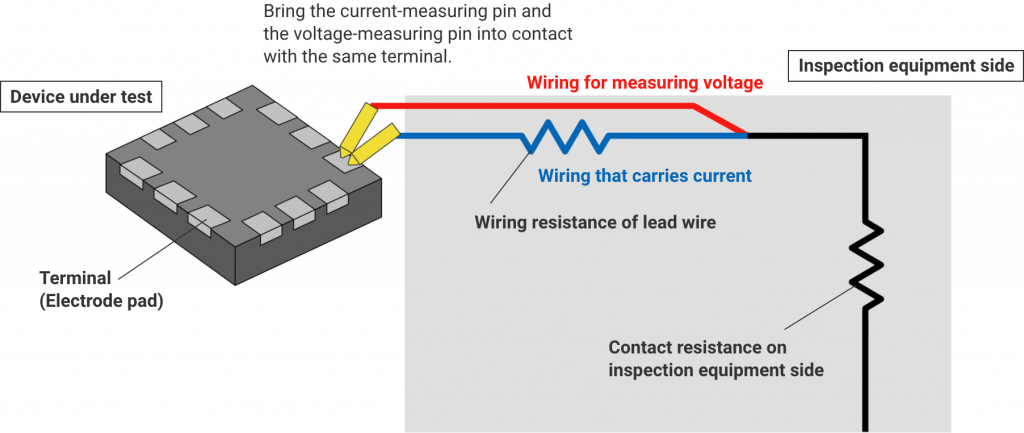

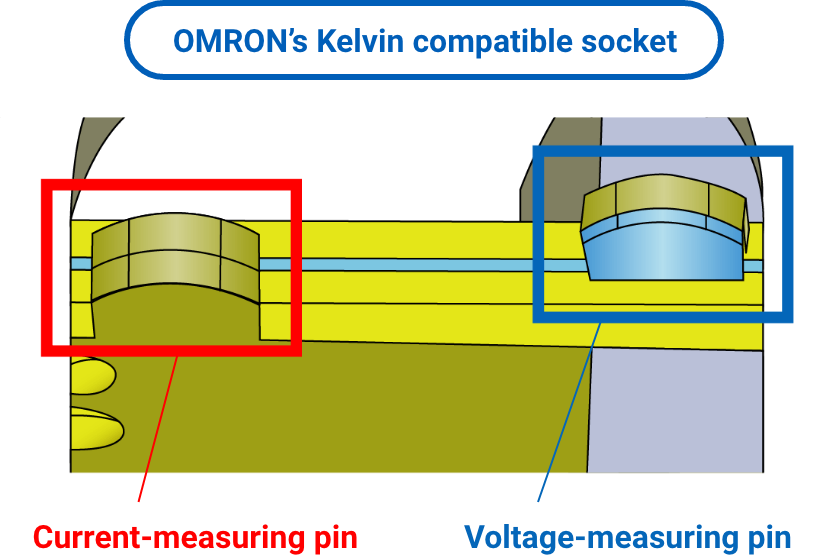

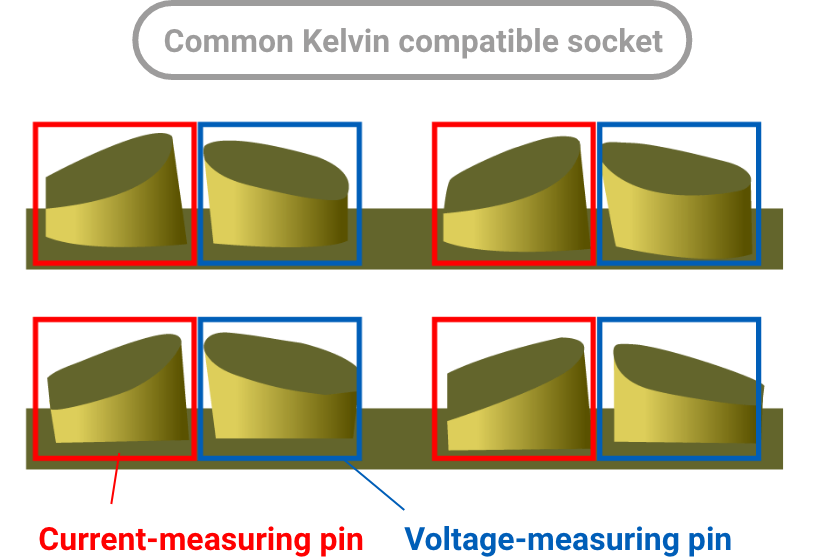

Kelvin Connection Compatible – High‑Density Terminals for Large Currents

Kelvin Connection for Accurate High‑Current Measurement

For power semiconductor inspections, OMRON’s Kelvin connection design separates current and voltage measurement terminals, eliminating the impact of lead and contact resistance. This ensures precise resistance measurement even at high currents.

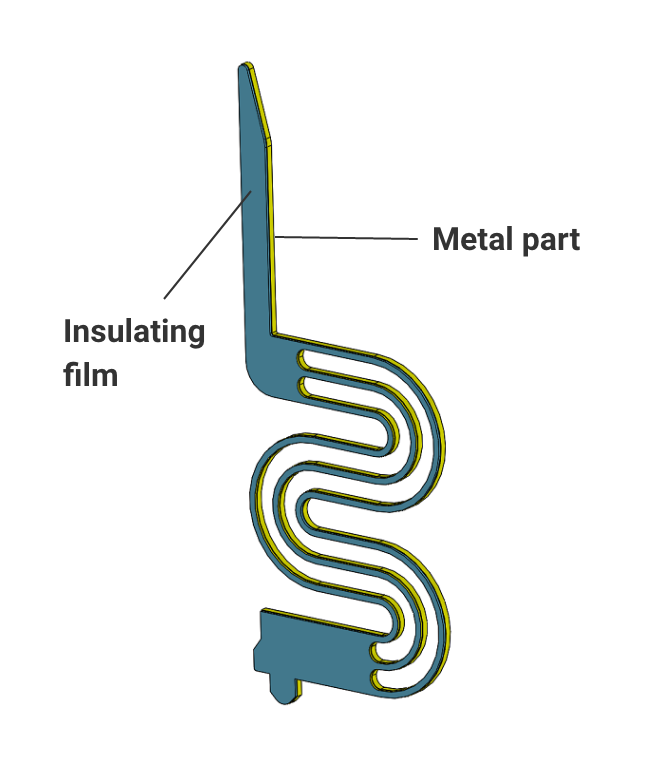

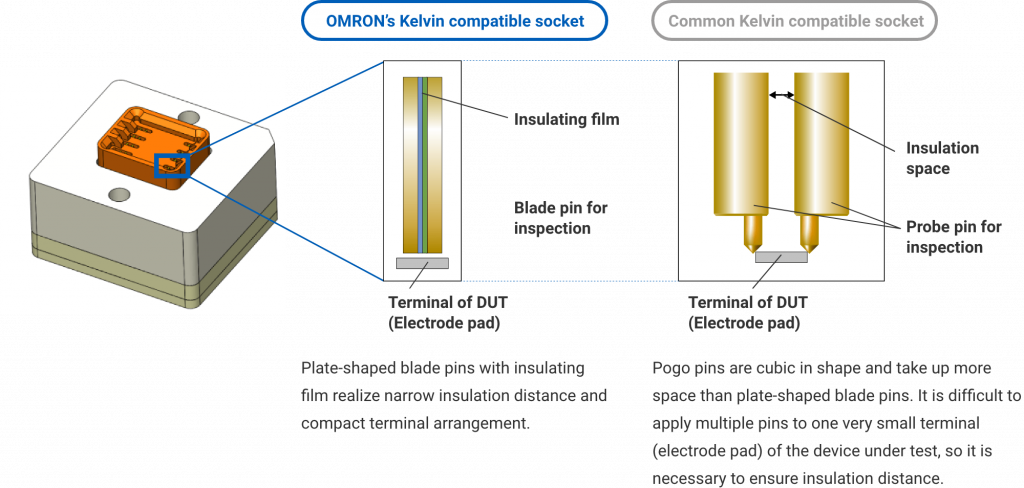

High‑Current Kelvin Measurement with Space‑Saving Blade Pins

OMRON’s high‑current Kelvin sockets use slim, plate‑shaped blade pins with insulating films, enabling multiple pins to contact the same terminal for larger current handling in small‑package devices. Unlike bulky pogo pins, this design saves space, maintains safe insulation, and supports accurate high‑current measurement even in tight layouts.

OMRON’s Kelvin compatible sockets allow current and voltage pins to be arranged separately within the same bundle by simply flipping the pins. This flexibility reduces terminal layout constraints and helps cut design and manufacturing time.

The pins for measuring current and voltage can be easily separated by simply flipping the terminals, making design and production easier.

Pins for measuring current and voltage are mixed, making design and production difficult.

High durability and reduced maintenance

Durable, Application‑Specific Sockets

OMRON’s custom design recommendations and patented material blend* make our sockets over five times more durable than pogo‑pin types, reducing replacements and improving inspection site efficiency.

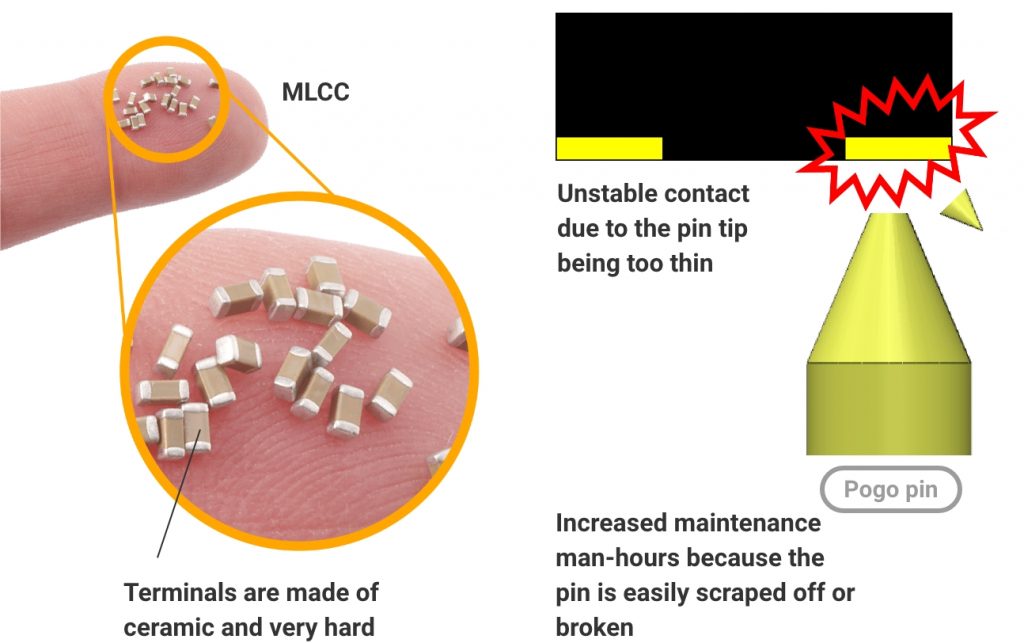

High‑Hardness Compatible Sockets for Ultra‑Small Devices

For tiny components like MLCCs, crystal oscillators, and SAW filters, conventional thin testing pins wear quickly, cause measurement variations, and risk damaging hard ceramic terminals. OMRON’s high‑hardness compatible sockets provide safe, durable, and accurate continuity inspection for these ultra‑small packages, reducing maintenance needs and improving production efficiency.

*Specifications are for reference only and may vary depending on the customized product.

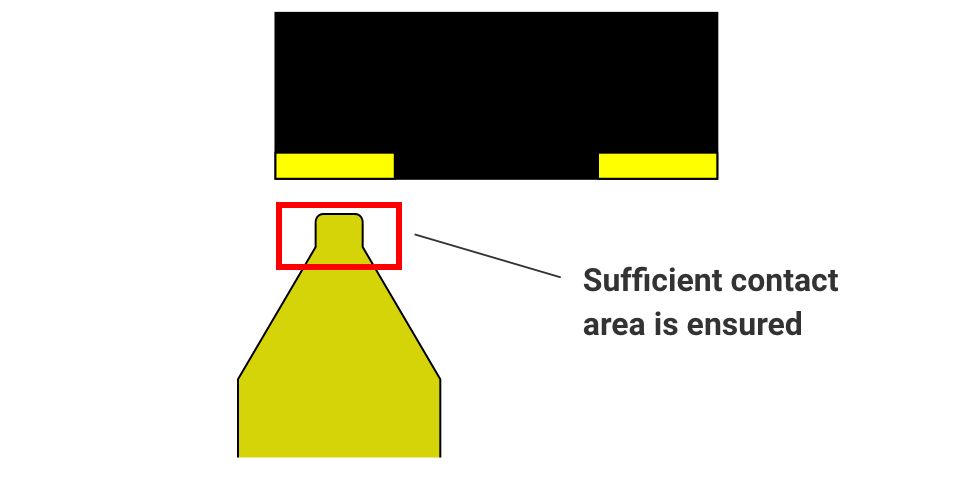

Stable contact for accurate inspections

OMRON’s convex‑tip sockets ensure a stable contact area with conduction pads, while EFC process technology maintains micron‑level dimensional accuracy—even with extremely small pins in mass production.

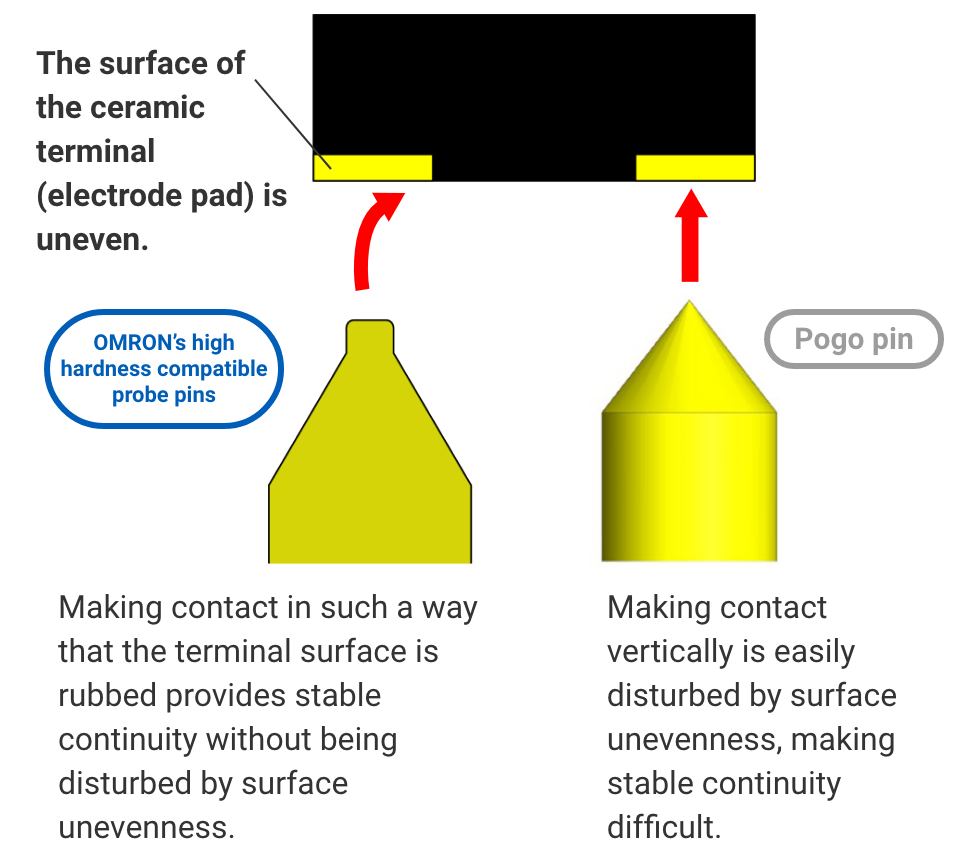

Reliable Contact for Small, Uneven Terminals

Small devices like crystal oscillators often have hard, uneven ceramic terminals, making accurate measurement difficult with vertical pogo pins. OMRON’s EFC‑technology blade pins use a spring action that rubs the terminal surface, ensuring reliable contact and stable measurement accuracy.

Omron’s probe pin (blade pin) movement for reliable contact

Long operating life and reduced maintenance

Durable Blade Pins for Stress‑Free Inspection

OMRON’s convex‑tip blade pins resist tip damage, reducing maintenance time and boosting production efficiency. Their robust design also minimizes the risk of damaging customer products, ensuring safe, stress‑free inspections.

Long‑Life Custom Sockets

OMRON’s application‑specific designs and patented material blend* make our sockets over five times more durable than pogo‑pin types, reducing replacements and improving inspection efficiency.

*Patent No. 5077479

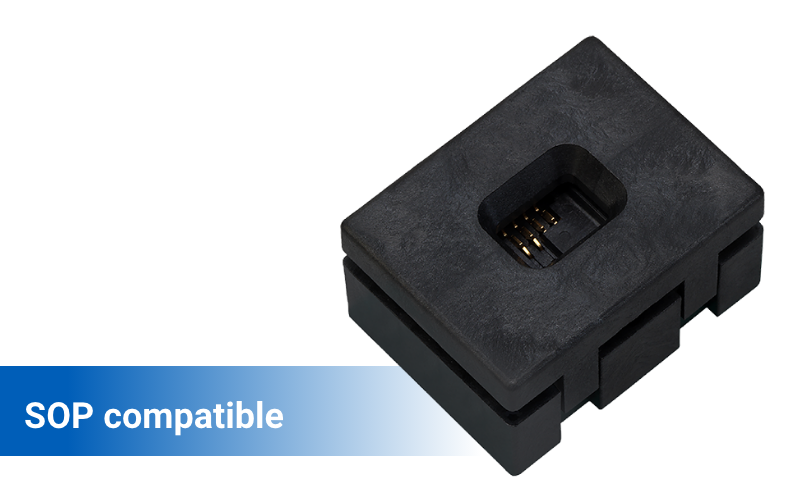

High‑Accuracy SOP Testing Without Damage

Delivers precise measurements for small SOP devices while protecting the device under test from damage.

*Specifications are for reference only and may vary depending on the customized product.

No damage to customer’s products

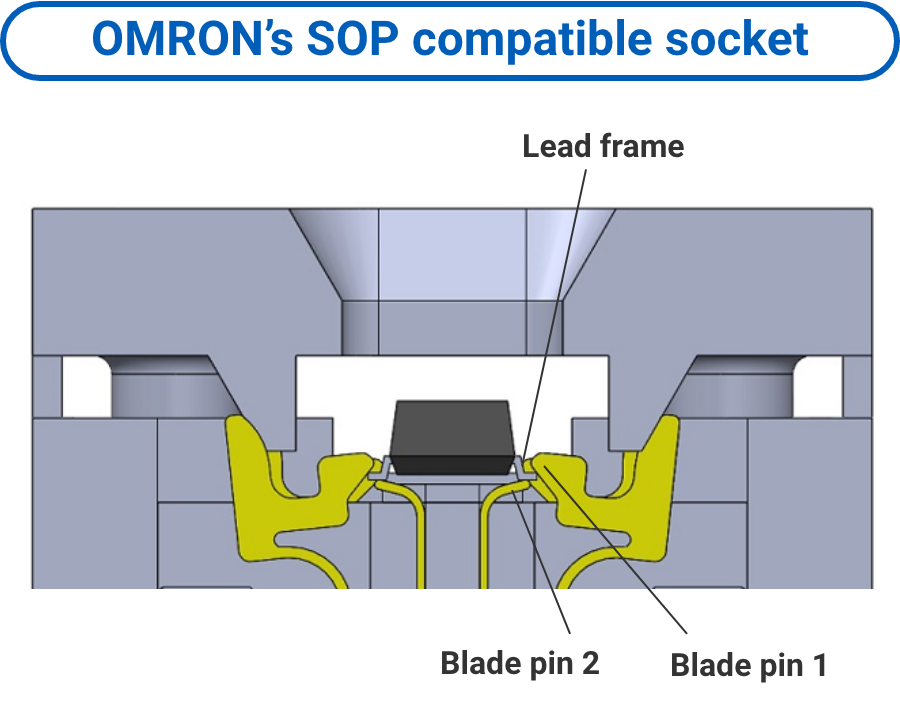

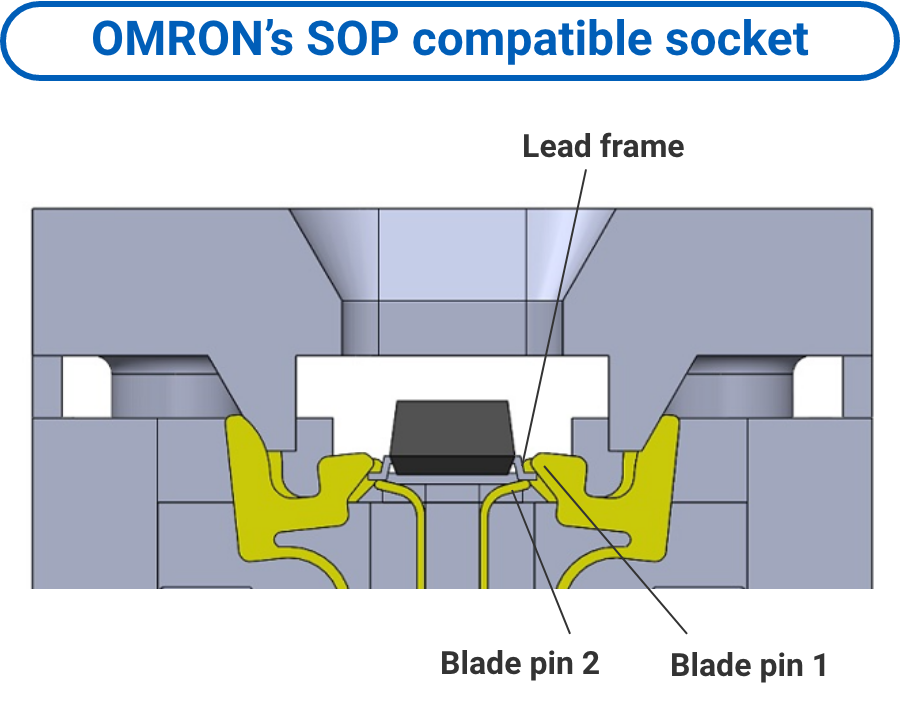

SOP Compatible Sockets

OMRON’s SOP sockets use blade pins that clamp the lead frame from both sides, minimizing stress and preventing deformation or damage during inspection of fragile small devices.

Gentle Lead Frame Clamping

Blade pins clamp the lead frame from both sides, preventing deformation and damage during testing.

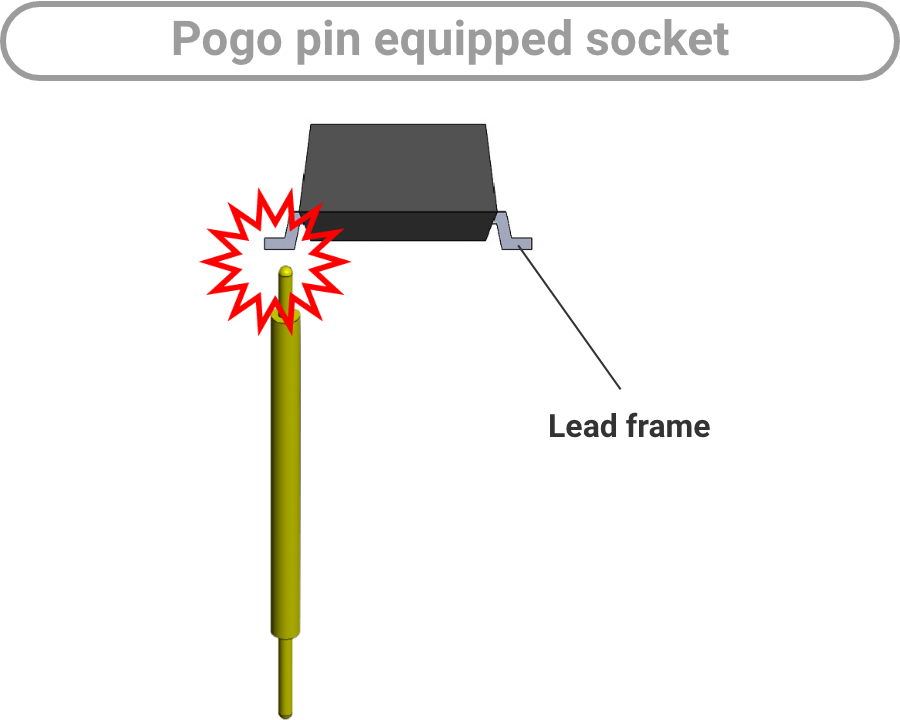

Lead Frame Deformation Issue

Pressing a rigid, rod‑shaped testing pin against a fragile lead frame can cause deformation.

Accurate measurements even in a small package

For small, unstable devices like SOP packages, OMRON’s SOP‑compatible sockets clamp the lead frame from both sides, ensuring precise contact force on each terminal. This design delivers stable electrical contact and high measurement accuracy.

Stable Lead Frame Contact

Blade pins clamp the lead frame from both sides, ensuring secure and stable contact during testing.

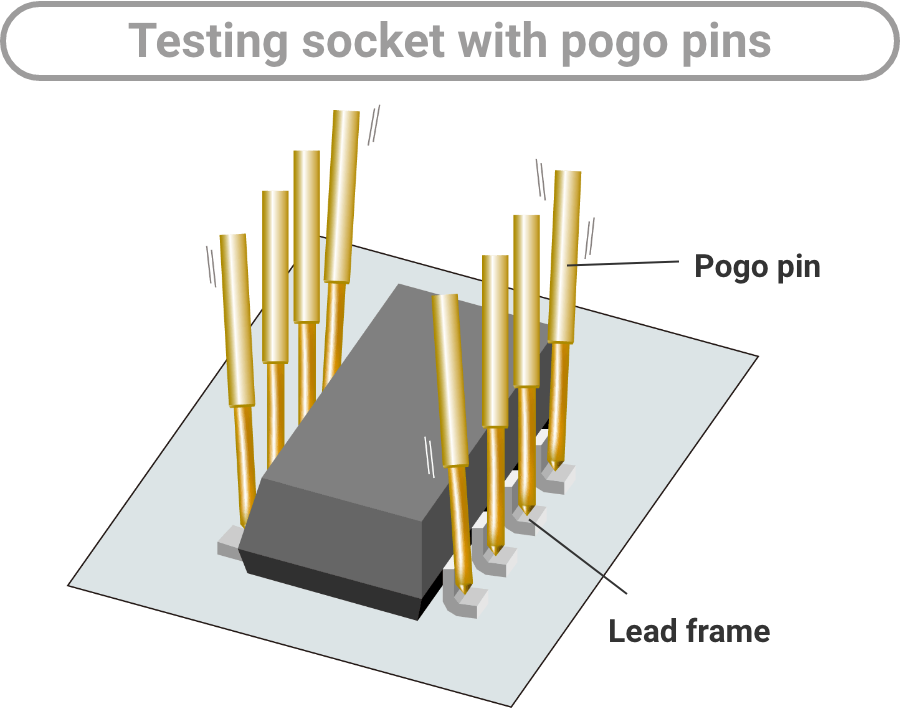

Point Contact Limitation

Rod‑shaped terminals make only point contact, making it difficult to accurately connect to the lead frame of small, unstable devices under test.

High durability and reduced maintenance

Durable SOP‑Compatible Sockets

OMRON’s patented material blend* and application‑specific designs make our SOP‑compatible sockets five times more durable than pogo‑pin types, reducing replacements and boosting inspection efficiency.

*Patent No. 5077479

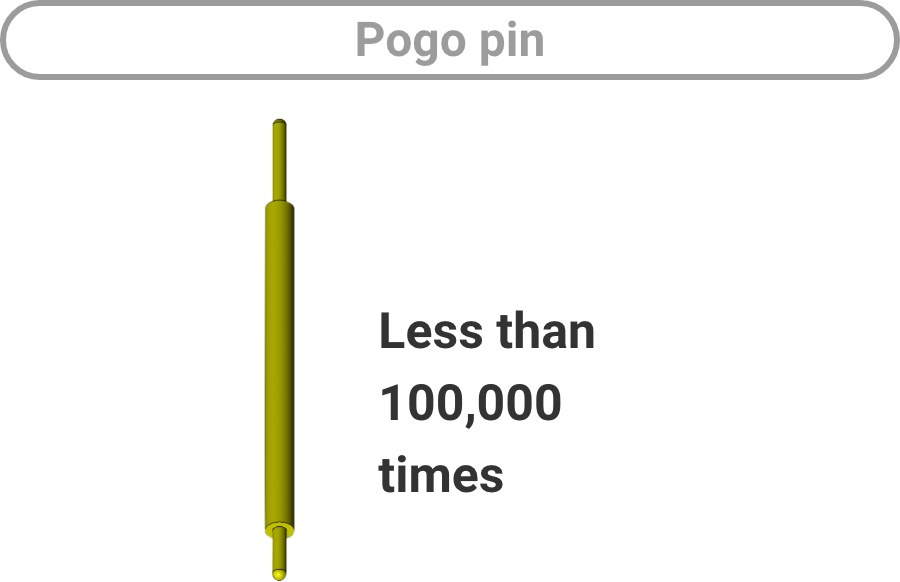

High‑Temperature Compatible Sockets

OMRON sockets withstand environments up to 200 °C, making them ideal for long‑term use in burn‑in tests that apply temperature and voltage loads to eliminate initial failures. Designed in the same size as pogo pins, they can easily replace existing pins.

*Specifications are for reference only and may vary depending on the customized product.

Usable in high temperature environments up to 200°C

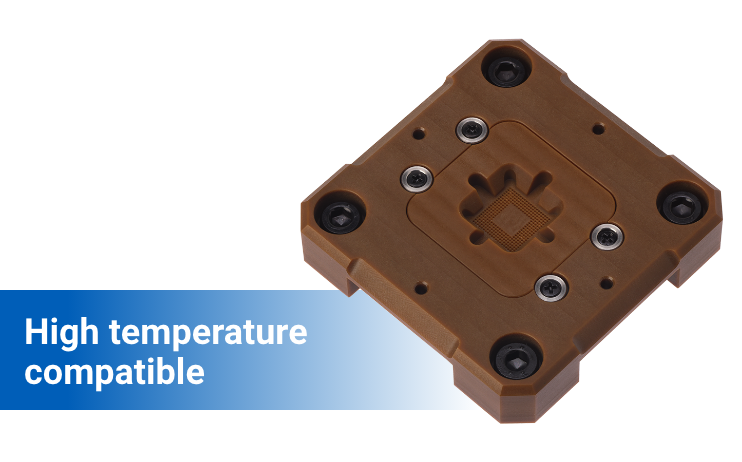

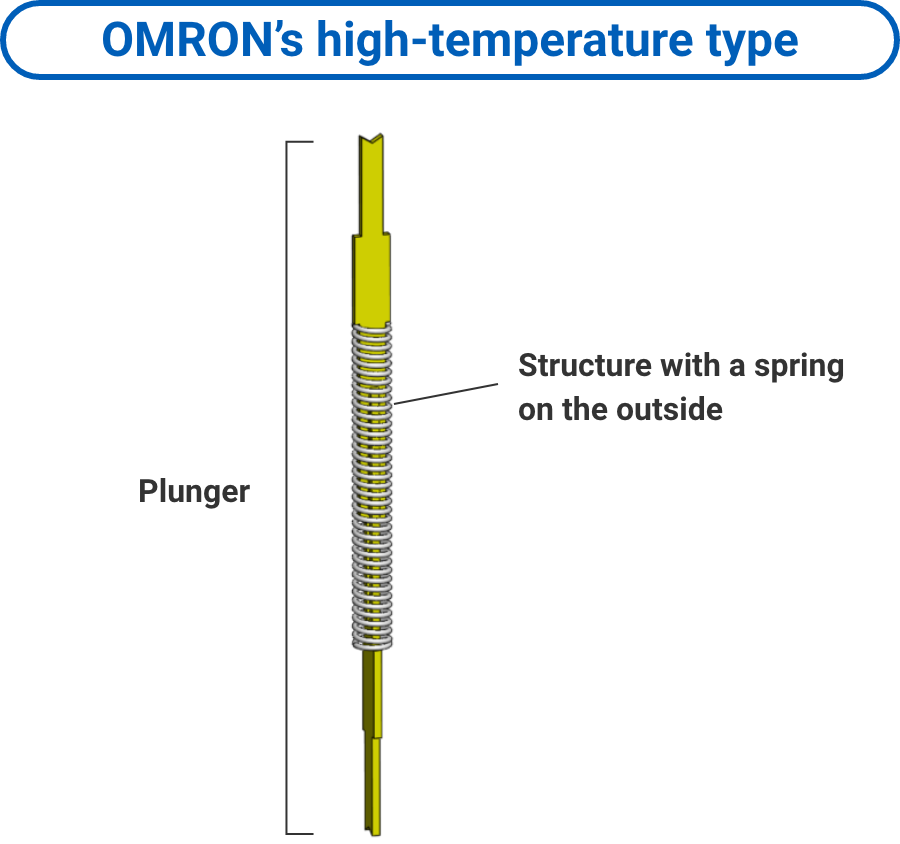

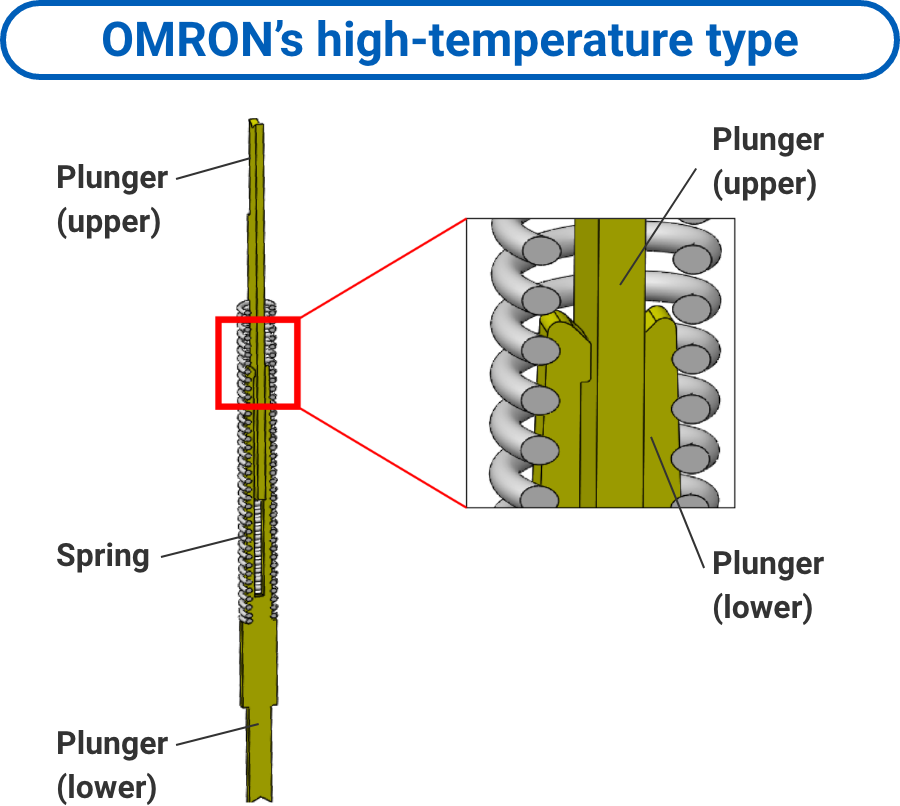

Unlike pogo pins with internal springs that risk welding at high temperatures, OMRON’s high‑temperature pins use an external heat‑resistant spring to prevent this issue. They maintain contact resistance of 100 mΩ or less even after 500,000 operations at 180 °C, ensuring accurate inspections without loss of performance or mechanical life.

Safe inspection with stable contact

In pogo pins, conduction depends on spring movement, which can affect contact stability. OMRON’s high‑temperature pins conduct when the lower plunger clamps the upper plunger from both sides, delivering strong, stable contact force. This design ensures accurate inspections without variations in contact resistance.

Stable Plunger Contact

Upper plunger clamps the lower plunger from both sides, ensuring consistent and reliable contact.

Unstable Spring‑Dependent Contact

Contact relies on the spring touching the plunger, making it prone to instability.

High durability and reduced maintenance

Durable SOP‑Compatible Sockets

OMRON’s patented material blend* and custom designs make our SOP‑compatible sockets five times more durable than pogo‑pin types, reducing replacements and improving inspection efficiency.

*Patent No. 5077479